Polychlorinated Biphenyl (PCB)-Containing Fluorescent Light Ballasts (FLBs) in School Buildings

The purpose of this web page is to provide information to school administrators and maintenance personnel on the hazards posed by PCBs in PCB-containing fluorescent light ballasts, how to properly handle and dispose of these items, and how to properly retrofit the lighting fixtures in your school to remove potential PCB hazards.

It should be noted that procedures outlined on this page (with the exception of disposal requirements) are a guide to assist building owners and operators. States may have mandatory and more stringent requirements than EPA.

- What are the risks?

- Identifying FLBs that may contain PCBs

- Cost savings associated with a retrofit of older lighting

- Recommended procedures for cleanup and decontamination

What are the risks?

PCBs are contained within the FLB capacitors and interior potting material of old, magnetic T12 lighting fixtures. The capacitor regulates the amount of electricity flowing into the lighting fixture, and the potting material insulates the FLB and reduces the "humming" noise. Because all PCB-containing FLBs currently in use have exceeded their designated life span, they are susceptible to leaking or rupturing. This may lead to increased exposure to building occupants. Residues from these sources are difficult and costly to clean up. Additionally, intact PCB-containing FLBs may emit small amounts of PCBs into the air during normal use of the lighting fixtures. EPA recommends all PCB-containing FLBs be removed from lighting fixtures.

NOTE: EPA has limited data suggesting older high intensity discharge (HID) ballast capacitors may be source of PCB exposure. EPA recommends that school administrators and building owners consider removing and replacing HID ballasts that contain PCBs.

In 1976, Congress banned PCB manufacturing in the United States due to their toxic effects. In July 1979, EPA phased out the processing and use of PCBs, except in totally enclosed equipment. Some PCBs installed before the 1976 ban or after 1979 may contain PCBs, and may still be used in schools around the United States.

EPA authorized the use of small capacitors in FLBs in 1982. However, if the capacitors leak, then the spill must be cleaned up within 24 hours and the leaking FLBs must be disposed of properly. This is in accordance with 40 Code of Federal Regulations (CFR) section 761.125 (c)(1) - Requirements for PCB Spill Cleanup and 40 CFR section 761.62 - Disposal of PCB Bulk Product Waste. EPA regulations also require that all FLBs built between July 1, 1979, and July 1, 1998, that do not contain PCBs must be labeled "No PCBs."

PCB-containing FLBs in School Buildings

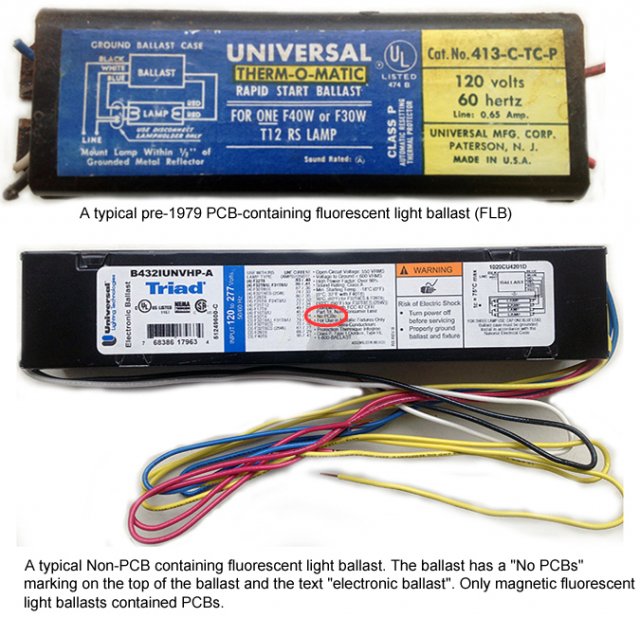

Schools in the United States built before 1979 may have PCB-containing FLBs. Only the T12 magnetic FLBs (not T8 or T5 FLBs) may contain PCBs. The "T" designates the lamp that goes with the FLB as "tubular" shape. The number after the "T" represents the lamp diameter in eighths of an inch.

As they age, the FLBs degrade and EPA has determined that intact and non-leaking FLBs can release PCBs into the air. Depending on the number of operating hours, operating temperature, and on/off cycles, the typical life expectancy of a magnetic FLB is 10 to 15 years. The total failure rate over the useful life of small capacitors in FLBs is about 10 percent (47 FR 37342, August 25, 1982). FLB failure rates increase significantly after this typical life expectancy. All of the pre-1979 FLBs in lighting fixtures that are still go beyond their typical life expectancy, increasing the risk of leaks, smoking conditions, or fires.

The oldest PCB-containing FLBs may lack thermal overload protection. Thermally protected FLBs are marked with a "P" as required by the National Electrical Code. FLBs without a "P" marking do not contain a mechanism to prevent overheating and are at a higher risk of failure and creating smoke conditions. The potential spread of PCBs can be worsened by the mishandling of personnel who are unaware of the presence of PCBs in FLBs. An FLB that has been damaged or mishandled can increase exposure PCBs.

Reports from schools across the country show that FLB failures are not uncommon. New York City public schools also found remote FLB cabinets in the hallways of 16 of their school buildings. These cabinets are essentially large high voltage electrical panels that house up to twenty FLBs.

Exposure to PCBs From FLBs in Schools

The most common way people are exposed to PCBs from FLBs is through breathing PCB-contaminated air or touching PCB-contaminated materials after an FLB leaks or catches fire. Where they remain, leaking FLBs can continue to release PCBs over several years and generate elevated levels of PCBs in the air. PCBs are persistent, bioaccumulative toxicants. This means that they are most harmful when exposure accumulates over a prolonged period of time.

Since the likelihood of harm increases with added exposure, the best protection is to remove leaking FLBs. Intact FLB capacitors can also lead to the presence of PCBs in school environments. PCB residues from previously failed FLB capacitors may remain in fixtures even after the FLB is replaced. Leaking or bursting capacitors are likely to substantially elevate PCB levels in indoor environments.

Steps should be taken so children and teachers do not continually spend time in an area with elevated PCB levels in their air. The affected area, classroom, hallway, cafeteria, or auditorium should be off limits to students and teachers during cleanup and decontamination activities. EPA developed Exposure Levels for Evaluation of PCBs in Indoor School Air to help in determining if you have an inhalation exposure concern. Exceeding these levels does not mean that adverse effects will occur. However, as exposure levels increase and persist over time, EPA has less confidence that the exposures will not result in adverse effects.

Read more information in the health effects of PCBs.

Identifying FLBs that May Contain PCBs

The following criteria are provided to help identify FLBs that may contain PCBs:

- FLBs manufactured before July 1, 1979, may contain PCBs

- FLBs manufactured between July 1, 1979, and July 1, 1998, that do not contain PCBs must be labeled "No PCBs"

- If an FLB is not labeled "No PCBs," it is best to assume it contains PCBs unless it is known to be manufactured after 1979

- FLBs manufactured after 1998 are not required to be labeled

If the FLB contains PCBs, they are located inside the small capacitor within the FLB or in the potting material (a black, tar-like substance that encapsulates the internal electrical components). There would be approximately one to one half ounces of PCBs in the capacitor and lower amounts in the potting material. If an FLB fails or overheats, the capacitor may break open resulting in release of its oils and potting materials.

PCBs may be present as a yellow, oily liquid or in the tar-like potting material that leaks from the FLB. The capacitor does not always leak when the FLB fails, and a leaking capacitor does not always cause FLB failure. A leaking or rupturing FLB may increase PCB levels in the air. So, measures should be taken to limit or avoid personal exposure.

Determining Whether PCB-containing FLBs are Present in Your School Building

Any structure built or renovated before 1979 could have PCB-containing FLBs if it has not undergone a complete lighting retrofit after 1979. In some cases, PCB-containing FLBs that were manufactured before 1979 were stored and later used in some fluorescent light fixtures installed or repaired after 1979.

To determine whether you school has PCB-containing FLBs, EPA recommends conducting a visual inspection of the FLBs in a representative number of light fixtures (not just the bulbs). Chapter seven of the HUD Guidelines for the Evaluation and Control of Lead Based Paint Hazards in Housing provides an example of how to determine what the representative number is.

Tips for How to Identify PCB-containing FLBs

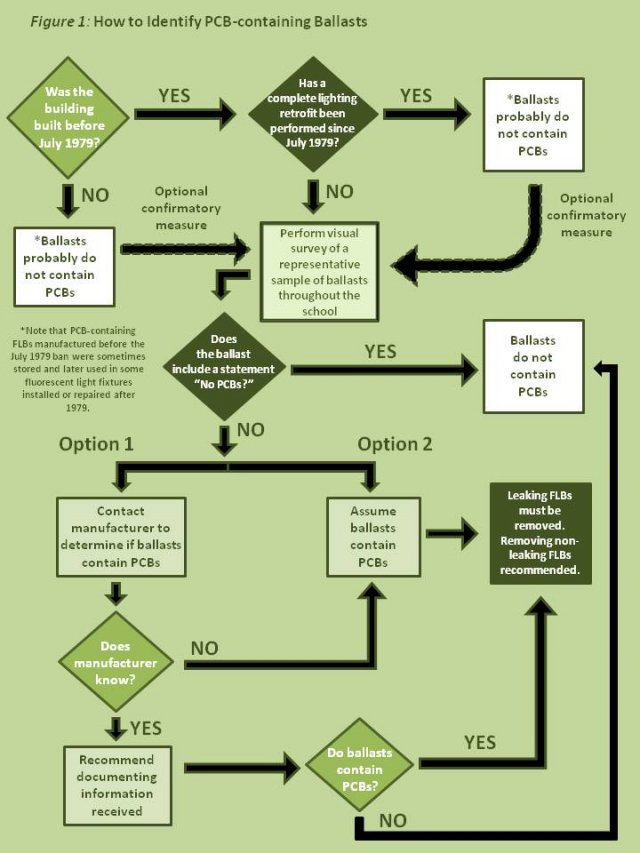

Figure 1: How to Identify PCB-containing Ballasts (click to enlarge) can help you determine whether there may be PCB-containing FLBs in your school. The FLBs are contained within light fixtures. Because you may need to open the fixtures to view the FLBs, select a representative number of each type of fixture in use throughout the school to inspect first. Inspection may be accomplished by removing a portion of the fixture, such as the metal panel covering the FLB. Expand you inspection if you find PCB-containing FLBs.

EPA recommends the following steps to prevent exposure if leaking FLBs are discovered:

- Wear protective clothing, including chemically resistant gloves selected for PCB resistance, disposable shoe covers and disposable overalls as prescribed by the Occupational Safety and Health Administration.

- Remove furniture and other classroom objects from under the fixtures.

- Cover the floor with plastic sheeting to capture any materials that leak from the FLB or fixture.

- Ventilate the room or use supplemental ventilation or respiratory protection to reduce the risk of breathing in fumes.

- Keep a record of the inspected areas (e.g., classroom numbers) and locations of the fixtures.

Consider the following options if the FLBs do not have the statement "No PCBs":

- Assume that the FLB contain PCBs

- Contact the manufacturer and provide the light fixture brand, model number and serial number to determine if the FLB contains PCBs. If the manufacturer is not sure, assume that it does.

Determining Whether to Replace the PCB-containing FLBs

It is important to always consider the health effects of leaving PCB-containing FLBs in place, as well as what could happen if an FLBs fails, leaks smokes or catches fire. An FLB failure can happen without warning at any time. An incident can also add to PCB levels in the air, which may pose health issues for the staff or students who are exposed. When an FLB has leaked, significant costs could be incurred to cover the following:

- Hiring experienced cleanup personnel

- Relocating students and teachers from the effected area into temporary quarters during cleanup and decontamination, which may disrupt school programs and functions

- Cleaning up and decontaminating exposed equipment and surfaces to required levels (40 CFR sections 761.61 or 761.79)

- Complying with environmental regulations for proper storage and disposal of contaminated equipment and cleanup materials (40 CFR sections 761.65 and 761.60)

Postponing lighting retrofits and upgrades by leaving PCB-containing FLBs in place may result in PCB exposure to your students and staff, and have additional cost impacts (e.g., lost school days, emergency spill clean-up costs, etc.).

On July 14, 2009, the Department of Energy (DOE) issued a final rule entitled Energy Conservation Standards and Test Procedures for General Service Fluorescent Lamps and Incandescent Reflector Lamps. The rule raised energy efficiency standards for certain fluorescent lamps for sale in the United States. After the DOE rule was promulgated, the manufacture of some T12 lamps used in fixtures that use PCB-containing FLBs were discontinued after July 14, 2012. This happened because they did not meet the new efficiency standards.

On January 26, 2015, DOE issued another final rule further increasing the energy efficiency standards for fluorescent lamps. As a result of these rulemakings, the supply of T12 lamps is expected to decrease over time and the cost of those that remain is expected to increase. This adds a greater incentive to perform a retrofit of PCB-containing T12 lighting. In addition to the rulemakings pertaining to fluorescent lamps, the DOE also increased energy efficiency standards for manufactured FLBs (including T12 FLBs). Although these newly manufactured FLBs do not contain PCBs, the energy efficiency standards, according to the DOE, will make it harder for T12 FLBs to be manufactured, which in turn is expected to further drive T12 fluorescent lamps from the market.

Cost Savings Associated with a Retrofit of Older Lighting

Replacing old lighting fixtures can not only increase energy efficiency and decreases energy costs, but may also increase property values, provides better lighting (in appearance and quality of light) and reduces the chance of emergency service situations. The retrofits can be done on an individual FLB basis (e.g., as found through visual inspection), or as part of a lighting retrofit which replaces the entire lighting fixture with newer, more energy efficient fixtures. A complete lighting retrofit eliminates the PCB hazards and increases energy efficiency by 30-50 percent (Refer to the Energy Star website for more detailed information).

Lighting retrofits to eliminate PCB-containing FLBs should be considered as a component of any remodeling effort. The T12 lamp and corresponding FLB is less energy efficient than other FLB lighting (e.g., T8 or T5 lighting). The cost of replacing these fixtures can typically be recouped in less than seven years depending upon hours of operation and local energy costs. Detailed information on the savings that may be achieved and potential funding that may be acquired through an investment in new lighting is available at the Energy Star website. The website also provides information about funding that may be available for the replacement of old fixtures.

In most states, there are several agencies and organizations with funding available to support energy-efficiency projects or provide ways to obtain financial assistance for making a building more energy efficient. Some of these programs cover conversion to more energy-efficient lighting. Additionally, many states, localities and utility companies have programs for energy-efficiency rebates and other benefits that may include converting to more energy-efficient lighting. DOE published a guide (pdf) (46pp, 1.92Mb) in April 2013 to assist schools in funding energy efficiency upgrades.

Recommended Procedures for Cleanup and Decontamination

An experienced contractor or facilities staff person remove, cleanup and decontamination PCB-containing FLBs that leak, smoke or catch fire. This includes management and disposal of PCB-containing wastes generated from cleaning up such incidents.

Steps for Cleanup and Decontamination after a PCB-containing FLB Leak, Smoking Condition or Fire

These steps are a guide to assist building owners and operators. Unique circumstances may be encountered in individual buildings and/or rooms. Contact your EPA Regional PCB Coordinator for questions.

Preparation

- Isolate the affected area from central ventilation and ventilate the area separately to prevent the spread of debris and dust to other areas.

- Workers should wear personal protective equipment (PPE), including disposable coveralls, chemically resistant gloves and disposable shoe covers selected for appropriate PCB penetration resistance, respirators equipped with organic vapor filters, and safety glasses.

- Move furniture and other classroom objects from under the fixtures, and cover the with plastic sheeting to capture any material that might leak from the fixture.

- Turn off the light fixtures or room switches. If present, turn off and lock out the fuses or breaker boxes that control the switches.

Inspection

- Remove the lamp cover or grille (baffle) of the light fixture to expose the fluorescent lamp (tube).

- If the fluorescent tube is not contaminated with PCBs, it can be reused or recycled as Universal Waste. If the fluorescent tube is contaminated with PCBs, carefully remove it and place it in an approved Department of Transportation (DOT) container.

- Visually inspect the exposed section of the light fixture for potential PCB leakage or residue from a fire or smoking condition. If the light fixture shows signs of PCB leakage, clean up according to step 2 of Cleanup and Disposal then return to this step.

Removal

- Remove the FLB enclosure cover (tray) within the light fixture to expose the FLBs.

- To visually inspect the cover and wires, remove the FLB by clipping and removing the wire at the face of the FLB; and the exterior of the FLB and the interior exposed section of the light fixture including the housing (with FLB removed).

- If leaking or staining is identified on the FLB or light fixture, carefully remove them and place the items directly in an approved DOT container.

Cleanup and Disposal

- If there is no leaking or staining identified on the light fixture, but there is asbestos-containing material (ACM) such as a coated wire, disposed of it as ACM waste. Otherwise, the fixture is not regulated PCB waste and can be recycled or disposed of as municipal solid waste.

- Clean up spills from PCB-contaminated light fixtures and leaking FLBs outside the light fixture (e.g., floors, desks, walls, etc.) (40 CFR section 761.61 or 761.79).

- Identify and properly manage PCB waste streams, including approved DOT containers, approved storage facilities (40 CFR section 761.65), manifests (40 CFR section 761.207), and records (40 CFR section 761.180), as provided below:

- Leaking FLBs - PCB Bulk Product Waste for incineration.

- Light fixtures contaminated with PCBs and associated clean-up waste (plastic sheeting, PPE, etc.) - PCB Remediation Waste for disposal in approved landfill.

- Light fixtures not contaminated by PCBs with ACM wires - ACM waste for disposal in approved landfill.

Fluorescent lamps not contaminated by PCBs – Universal waste for recycling.

Steps for Performing a Retrofit for Non Leaking PCB-Containing FLBs in Schools

This section addresses non-leaking or otherwise uncontaminated FLBs. If you encounter a PCB-containing FLB that has leaked, caught fire, or smoked, refer back to the previous section Steps for Cleanup and Decontamination after a PCB-containing FLB Leak, Smoking Condition or Fire.

An experienced contractor or experienced facilities staff person should perform the lighting retrofit. Suggested steps include:

Preparation

- Turn off the light fixtures or room switches. In addition, turn off and lock out the fuses or breaker boxes that control the switches to the light fixtures or the fixtures directly.

Inspection

- Remove the lamp cover or grille (baffle) of the light fixture to expose the fluorescent lamp (tube).

- If the fluorescent tube is not contaminated with PCBs, it can be reused or recycled as Universal Waste. If the fluorescent tube is contaminated with PCBs, carefully remove it and place it in an approved DOT container.

- Visually inspect the exposed section of the light fixture for potential PCB leakage or residue. If the light fixture shows signs of PCB leakage, immediately refer back to Steps for Cleanup and Decontamination after a PCB-containing FLB Leak, Smoking Condition or Fire.

Removal

- Remove the FLB enclosure cover (tray) within the light fixture to expose the FLBs.

- To visually inspect the cover and wires, remove the FLB by clipping and removing the wire at the face of the FLB; and the exterior of the FLB and the interior exposed section of the light fixture including the housing (with FLB removed).

- Place the FLB directly in an approved DOT container.

Disposal

- If no leaking or staining is identified on the light fixture, but there is ACM, dispose of it ACM waste. Otherwise, the fixture is not regulated PCB waste and can be recycled or disposed of as municipal solid waste.

- Identify and properly manage PCB waste streams, including, where appropriate, the use of approved DOT containers, approved storage facilities (40 CFR section 761.65), manifests (40 CFR section 761.207), and records (40 CFR section 761.180), as provided below:

- Leaking FLBs - PCB Bulk Product Waste for incineration.

- Light fixtures contaminated with PCBs and associated clean-up waste (plastic sheeting, PPE, etc.) - PCB Remediation Waste for disposal in approved landfill.

- Light fixtures not contaminated by PCBs with ACM wires - ACM waste for disposal in approved landfill.

Fluorescent lamps not contaminated by PCBs – Universal waste for recycling.

Check out the TSCA Disposal Requirements for FLBs for additional disposal options for PCBs and non-PCB-containing FLBs.