Monitoring by Control Technique - Thermal Oxidizer

Description

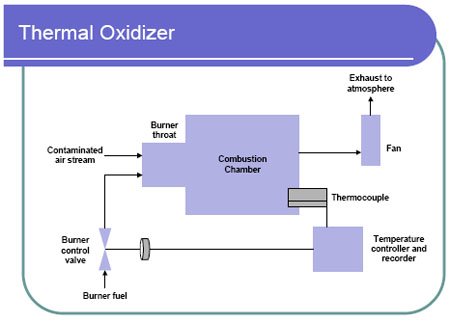

Thermal oxidizers, or thermal incinerators, are combustion devices that control VOC, CO, and volatile HAP emissions by combusting them to carbon dioxide (CO2) and water. Thermal oxidizers are similar to catalytic oxidizers (catalytic oxidizers use a catalyst to promote the oxidation reaction). Important design factors include temperature (a temperature high enough to ignite the organic constituents in the waste stream), residence time (sufficient time for the combustion reaction to occur), and turbulence or mixing of the combustion air with the waste gas.

To reduce fuel usage required for oxidation, thermal oxidizers frequently have some form of heat recovery. The percentage of heat recovery in the design of thermal oxidizers generally increases with decreasing inlet VOC/HAP concentration. Heat recovery may either be recuperative or regenerative. In recuperative heat recovery, heat is recovered by passing the hot exhaust gases through a non-contact air-to-air heat exchanger, to heat the incoming air to the oxidizer. In regenerative heat recovery, hot exhaust gases and cool inlet gases are alternatively passed through a fixed bed, typically employing ceramics. See the link below for a schematic of a basic thermal oxidizer.

A training tool developed for inspectors provides an overview of oxidizers (thermal and catalytic); this tool describes oxidizer types, operating principles, pollutants controlled, proper operating conditions, and performance monitoring of oxidizers. A training video provides similar information in an audio-video format (about 15 minutes in length). Other specific information about thermal oxidizers can be found from the EPA Air Pollution Control Cost Manual, Section 3.2, Chapter 2 - Incinerators and from EPA Fact Sheets.

For more information, see the box More About Thermal Oxidizers.

Monitoring Information

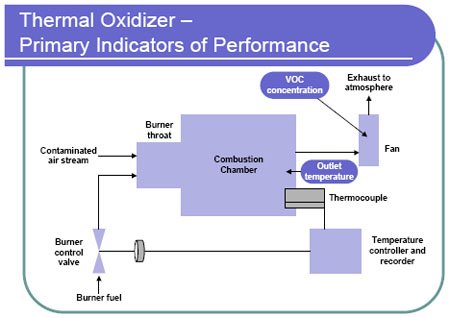

For VOC control, the primary indicators of thermal oxidizer performance are the outlet exhaust gas VOC concentration and the combustion chamber temperature. Other indicators of thermal oxidizer performance include outlet exhaust gas CO concentration, exhaust gas flow rate, fan current, outlet CO2 concentration, outlet O2 concentration, and auxiliary fuel line pressure. For CO control, the indicators of performance are the same as for VOC control, with the exception of outlet VOC and CO2 concentrations, which would not be monitored for a CO emissions limit.

The Compliance Assurance Monitoring (CAM) Technical Guidance Document (TGD) provides a source of information on monitoring approaches for different types of control devices.

Specific information provided in CAM TGD - Appendix A: Example CAM Submittals for Thermal Oxidizers, include example CAM submittals based on case studies of actual facilities.

For more information and to read the TGD, see the box Monitoring and the CAM Rule.

To search for additional monitoring information specific to an industry, see the monitoring information by industry type page.

Costs

Costs of thermal oxidation are discussed in the EPA Air Pollution Control Cost Manual*, Section 3.2, Chapter 2 - Incinerators(64 pp, 182 K, About PDF). Costs of monitoring systems, both Continuous Emission Monitors and parametric monitoring systems, are addressed in the EPA Air Pollution Control Cost Manual*, Section 2, Chapter 4 - Monitors.(42 pp, 542 K, About PDF)

Costs for thermal oxidation of styrene emitted from fiber-reinforced plastics facilities is discussed in a report titled, Assessment of Styrene Emission Controls for FRP/C and Boat Building Industries (EPA-600/R-96-109). The report includes spreadsheets designed to quickly analyze the control cost for a thermal oxidation (and other VOC/HAP control technologies) based on control device input flow rate and pollutant loading (in tons per year or ppm). An introductory text file lists the controls that are analyzed and gives basic instructions for using the spreadsheets. The spreadsheets were developed for styrene (C8H8, 4.326 mg/m3 per ppm, 0.00475 Btu/ppm) and would need to be altered to address other pollutants.

For more information, see the box More About Costs for Thermal Oxidizers.

More About Thermal Oxidizers

- Air Pollution Control Cost Manual*, Section 3.2, Chapter 2 - Incinerators (PDF)(64 pp, 182 K, About PDF).

- EPA Fact Sheet - Thermal Incinerator, EPA-452/F-03-022 (PDF)(6 pp, 30 K, About PDF)

- EPA Fact Sheet - Incinerator - Recuperative Type, EPA-452/F-03-020 (PDF)(6 pp, 30 K, About PDF)

- EPA Fact Sheet - Incinerator - Regenerative Type, EPA-452/F-03-021 (PDF)(5 pp, 26 K, About PDF)

- More About Catalytic Oxidizers

- Training Video- Air Pollution Control Devices - Vapor Incineration (MP4) (zip)

- CAM TGD Appendix A: Thermal Oxidizers

- CAM Rule(48 pp, 408 K, About PDF) - Federal Register - October 22, 1997

- Spreadsheets to Analyze Control Costs for Catalytic Oxidizers, from Assessment of Styrene Emission Controls for FRP/C and Boat Building Industries, EPA-600/R-96-109 (ZIP)(32 K, 1996) (Excel and Lotus 1-2-3 files)

- Introductory Text; Assessment of Styrene Emission Controls for FRP/C and Boat Building Industries (EPA-600/R-96-109) (txt)

- Assessment of Styrene Emission Controls for FRP/C and Boat Building Industries (EPA-600/R-96-109) (132 pp, 6 M, About PDF)

- Addendum to Assessment of Styrene Emission Controls for FRP/C and Boat Building Industries, EPA-600/R-96-136 (PDF)(59 pp, 3 MB, About PDF)