CHP Benefits

CHP offers a number of benefits compared to conventional electricity and thermal energy production, including:

Efficiency Benefits

CHP needs less fuel to produce a given energy output and avoids transmission and distribution losses that occur when electricity travels over power lines.

The average efficiency of fossil-fueled power plants in the United States is 36 percent. This means that 64 percent of the energy used to produce electricity at most power plants in the United States is wasted in the form of heat discharged to the atmosphere.

Most facilities produce heat with natural gas boilers, which are generally 75–85 percent efficient at converting fuel to thermal energy. Overall, separate heat and grid power is 50–55 percent fuel-efficient.

By recovering and using heat from on-site electricity production, CHP systems typically achieve total system efficiencies of 65 to 80 percent. Some systems achieve efficiencies approaching 90 percent.

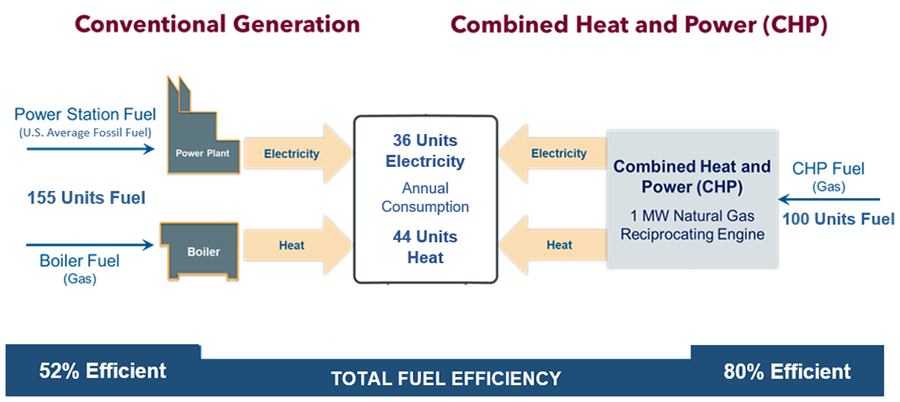

The illustration below demonstrates the efficiency gains of a 1 MW natural-gas-fired reciprocating engine CHP system compared to conventional production of electricity and useful thermal energy (i.e., purchased grid electricity and thermal energy from an on-site boiler).

Conventional Generation vs. CHP: Overall Efficiency

A CHP system’s efficiency depends on the technology used and the system design. The five most commonly installed CHP power sources (known as “prime movers”) offer these efficiencies:

- Reciprocating engine: 75–80 percent

- Combustion turbine: 65–70 percent

- Steam turbine: 80 percent

- Microturbine: 60–70 percent

- Fuel cell: 55–80 percent

The Catalog of CHP Technologies contains detailed information about these technologies.

Avoided Transmission and Distribution Losses

By producing electricity on-site, CHP also avoids transmission and distribution losses that occur when electricity travels over power lines. Within the five major power grids in the United States, average transmission and distribution losses vary from 5.2 percent to 5.6 percent on average, with a national average of 5.3 percent (Source: eGRID). Losses can be even higher when the grid is strained and temperatures are high. By avoiding losses associated with conventional electricity supply, CHP further reduces fuel use, helps avoid the need for new transmission and distribution infrastructure, and eases grid congestion when demand for electricity is high.

Environmental Benefits

Because less fuel is burned to produce each unit of energy output and because transmission and distribution losses are avoided, CHP reduces emissions of GHGs and other air pollutants. This means it can play an important role in decarbonizing energy production.

CHP systems offer considerable environmental benefits over purchased electricity and thermal energy produced on-site. Because they capture and use heat that would otherwise be wasted from the production of electricity, they need less fuel to produce the same amount of energy.

Because less fuel is combusted, GHG emissions, such as carbon dioxide (CO2), as well as other air pollutants like nitrogen oxides (NOx) and sulfur dioxide (SO2), are reduced.

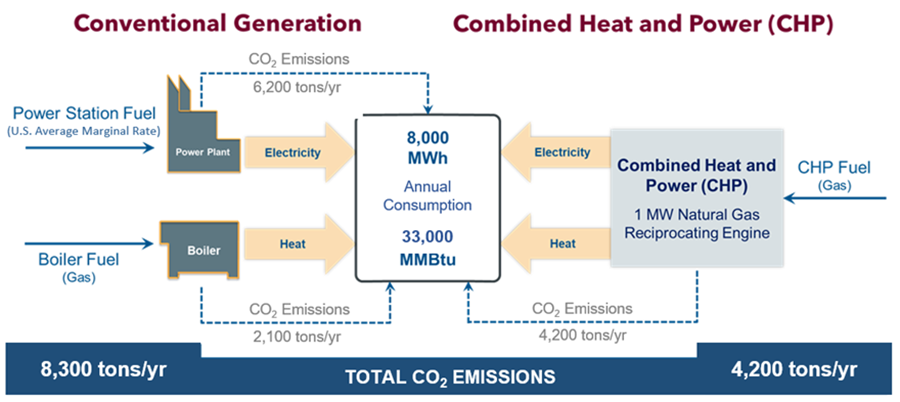

The following diagram shows the magnitude of reduced CO2 emissions of a 5 MW natural-gas-fired CHP system compared to the same energy output from conventional sources.

Conventional Generation vs. CHP: CO2 Emissions

Economic Benefits

CHP can offer a variety of economic benefits, including:

- Reduced energy costs: CHP reduces energy bills because of its high efficiency. By using waste heat recovery technology to capture wasted heat associated with electricity production, CHP systems typically achieve total system efficiencies of 60 to 80 percent, compared to 50 percent for conventional technologies (i.e., purchased utility electricity and an on-site boiler). Basically, they need less fuel for a given unit of energy output. Also, because they typically use natural gas—which is often cheaper than purchased electricity—they can help reduce electricity bills. Bills are further reduced because the CHP output reduces electricity purchases.

- Avoided capital costs: CHP can often reduce the cost of replacing heating equipment. Buildings can also be connected to a CHP-based district energy system that provides district heating (steam or hot water) and district cooling services (chilled water) for space heating, domestic hot water, and air conditioning. Such services avoid on-site equipment and save valuable building and rooftop space for other revenue-generating uses.

- Protection of revenue streams: Through on-site generation and improved reliability, CHP can allow facilities to continue operating in the event of a disaster or an interruption of grid-supplied electricity.

- Less exposure to electricity rate increases: Because less electricity is purchased from the grid, facilities have less exposure to rate increases. In addition, a CHP system can be configured to operate on a variety of fuel types, such as natural gas, biogas, coal, and biomass; therefore, a facility could build in fuel switching capabilities to hedge against high fuel prices.

Reliability and Resiliency Benefits

A reliable energy supply means that electricity is available to facilities when it is needed and without interruption. A resilient facility is one that can anticipate, prepare for, respond to, and recover from energy outages caused by storms or other adverse events. Unreliable electricity service represents a quantifiable business, safety, and health risk for some companies and organizations. CHP is an on-site generation resource and can be designed to operate independently from the electric grid to enhance facility reliability. In addition to enhancing reliability, CHP systems can be designed to continue operating in the event of a disaster or grid disruption to provide power for critical functions, thereby enhancing facility resiliency. Learn more about CHP’s role in providing electricity reliability and resiliency.