Underground Storage Tank Technical Compendium about the 2015 UST Regulation

This compendium contains EPA’s interpretations and guidance about the 2015 underground storage tank (UST) regulation. Questions and answers are presented in these categories:

- Applicability

- Implementation

- State program approval

- Spill buckets, under dispenser containment sumps, containment sumps

- Secondary containment and interstitial monitoring

- Overfill protection

- Internal lining

- Walkthrough inspections

- Release detection

- Compatibility

- Release reporting

- Temporarily out of use facilities

- Partially excluded USTs

- Statistical inventory reconciliation

- Field-constructed tanks and airport hydrant systems

- Emergency power generators

- Repairs to UST systems

- Aboveground releases

Does the 2015 Federal UST Regulation Apply to You?

These questions and answers pertain to the 2015 revised federal UST regulation. Many states and territories (referred to as states) have state program approval from EPA. To find a list of states with state program approval, see State Underground Storage Tank (UST) Programs.

- If your UST systems are located in a state with state program approval, your requirements may be different from those described in this compendium. To find information about your state’s UST regulation, contact your implementing agency or visit its website. You can find links to state UST websites at Underground Storage Tank (UST) Contacts: States.

- If your UST systems are located in a state without state program approval, both the requirements discussed in this compendium and the state requirements apply to you. To make sure you are in compliance, you should follow the more stringent requirement.

- If your UST systems are located in Indian country, these questions and answers apply to you.

Applicability

Question: Are there any exemptions to the new regulation? Or are all USTs covered? For example, is there an exemption for a 1,000-gallon UST that is filled with heating oil? (Added: September 2015)

Answer: The 2015 UST regulation discusses partial and complete exclusions from applicability in 40 CFR 280.10 and definitional exemptions in 40 CFR 280.12 (see the definition of underground storage tank). See the UST regulations.

The definition of underground storage tank at 40 CFR 280.12 exempts tanks used to store heating oil for consumptive use on the premises where stored. So if this is a heating oil tank where the contents are used on the site where that tank is located, then EPA would not regulate this tank.

Note that state UST programs may regulate tanks that EPA excludes from regulation or exempts by definition.

Process of Determining if UST storing Motor Fuel Additive is Petroleum UST or Hazardous Substance UST

Question: If the owner of a retail service station has an underground storage tank (UST) that stores motor fuel additive which is blended into the motor fuel UST with each delivery of motor fuel, is the UST storing the motor fuel additive considered a petroleum UST or a hazardous substance UST?

Answer: The fuel additive being stored is typically a mixture of petrochemicals, various other chemicals, and proprietary detergents.

Pertinent information can be found in the preamble to the 1988 UST regulations which provides the following information (information found at Federal Register / Vol. 53, No. 185 / Friday, September 23, 1988 / pages 37123 – 37124):

(12) Hazardous Substance UST System. "Hazardous substance UST system" means an UST system containing either (a) hazardous substances defined in section 101(14) of the Comprehensive Environmental Response, Compensation, and Liability Act of 1980 (but not including any substance regulated as a hazardous waste under Subtitle C) or (b) any mixture of such substances and petroleum that is not regulated as a petroleum UST system. Thus, the final rule, in effect, defines a hazardous substance UST system as any UST system storing regulated substances which is not a petroleum UST system. It is essentially a catchall for any UST system for which the effectiveness of petroleum release detection and corrective action technology is uncertain ...

[T]he final rule lists specific substances subject to the petroleum UST system requirements and uses a de minimis standard to determine when other mixtures of petroleum and hazardous substances are subject to petroleum UST system standards. A “petroleum UST system" is, thus, one which contains petroleum or petroleum and de minimis amounts of other regulated substances. Any other UST system is a hazardous substance UST system and must be provided with secondary containment or obtain a variance. The de minimis amount of hazardous substance mixed with a petroleum product is that amount in which the additional hazardous substance does not alter the detectability, effectiveness of corrective action, or toxicity of the petroleum to any significant degree.

The federal UST regulations provide the following definitions (40 CFR 280.12):

Regulated substance means:

(1) Any substance defined in section 101(14) of the Comprehensive Environmental Response, Compensation and Liability Act (CERCLA) of 1980 (but not including any substance regulated as a hazardous waste under subtitle C); and

(2) Petroleum, including crude oil or any fraction thereof that is liquid at standard conditions of temperature and pressure (60 degrees Fahrenheit and 14.7 pounds per square inch absolute).

The term regulated substance includes but is not limited to petroleum and petroleum-based substances comprised of a complex blend of hydrocarbons, such as motor fuels, jet fuels, distillate fuel oils, residual fuel oils, lubricants, petroleum solvents, and used oils.

Petroleum UST system means an underground storage tank system that contains petroleum or a mixture of petroleum with de minimis quantities of other regulated substances. Such systems include those containing motor fuels, jet fuels, distillate fuel oils, residual fuel oils, lubricants, petroleum solvents, and used oils.

Hazardous substance UST system means an underground storage tank system that contains a hazardous substance defined in section 101(14) of the Comprehensive Environmental Response, Compensation and Liability Act of 1980 (but not including any substance regulated as a hazardous waste under subtitle C) or any mixture of such substances and petroleum, and which is not a petroleum UST system.

In this specific situation, the manufacturer of motor fuel additives provided the Safety Data Sheet (SDS) for the additive. The SDS indicated that the constituents include CERCLA hazardous substances. The main constituent (carrier fluid) is listed as xylene and in addition, the SDS lists these other CERCLA hazardous substances in the additive: ethyl benzene, naphthalene, and toluene. The SDS did not list other CERCLA chemicals that are normally found in gasoline. This leads to the conclusion that the manufacturer did not use gasoline as the carrier fluid, but instead used the refined chemical of xylene in pure or almost pure form. In addition, the SDS indicated that the concentration of xylene is at a higher concentration than what would be found in gasoline.

Based on the above definitions, information from the 1988 preamble, and the information provided by the motor fuel additive manufacturer, the motor fuel additive in this specific situation is not one of the listed categories of petroleum (i.e., the additive is not a motor fuel/cannot be burned on its own as a motor fuel) and is not a complex blend of hydrocarbons. Xylene, ethyl benzene, naphthalene and toluene are all petrochemicals but appear to be in the additive as refined chemicals not as part of the full spectrum of the components that would be listed if gasoline were used as the carrier fluid. Since the motor fuel additive does not meet the definition of petroleum and there are CERCLA hazardous substances in the additive, an UST storing this motor fuel additive at a retail service station should be categorized as a hazardous substance UST.

A Specific Example: A retail service station stores motor fuel additive Ultrazol GA9058 in an UST. A review of the components of the additive shows 40 – 50% of the additive is xylene. Based on the reasons noted above, the UST storing Ultrazol GA9058 is considered a hazardous substance UST.

Applicability Determination of the UST regulations when there are combinations of underground and aboveground tanks.

Question: Do the UST regulations apply to a storage tank system at a truck stop where there is a large aboveground tank connected to several underground tanks (all storing the same product)? Does this determination change if there is an additional aboveground tank storing high percentage biodiesel that is blended with petroleum diesel from another aboveground tank to form a lower percentage biodiesel being stored in the underground tanks? Are any of these tanks subject to the SPCC/FRP 1 requirements? (Added: October 2023)

Answer:

There are four related scenarios that need to be addressed in order to answer the questions above.

- The first and second scenarios relate to determining what is included in an UST storage system when there is a large field-constructed AST as part of the system, and all tanks are storing the same substance.

- The third scenario relates to how this determination might change if a tank containing 100 percent biodiesel (i.e., B100), a substance not regulated by the UST program, is connected to the storage system to be blended into another product being stored.

- The fourth scenario relates to how this determination might change if a tank containing 99 percent biodiesel (i.e., B99) or any lower quantities of biodiesel, which are all substances regulated by the UST program, is connected to the storage system to be blended into another product being stored.

EPA uses the general term storage system to help users determine if their storage systems must comply with the 2015 UST regulation (40 CFR part 280). For this discussion, storage system means all aboveground tanks, underground tanks, and underground piping, but does not include aboveground piping. Although we use the term storage system in this scenario, it is not a federally defined term.

Note 1: The following scenarios involve having a large AST at a fueling location which may be restricted or not allowed under State Fire Codes. The answers here assume that the owner has received the required approvals to have this configuration.

Note 2: The following scenarios discuss various configurations in which diesel and biodiesel are stored or blended in different arrangements at a fuel dispensing facility. Since 1988, EPA’s UST regulations require fuel to be stored in systems that are compatible with the type of fuel being stored. Please note that compatibility extends beyond the fuel tank. Owners and operators must demonstrate compatibility for several components of their UST system to store substances containing more than 10 percent ethanol or more than 20 percent biodiesel. To learn more about compatibility compliance requirements, see this portion of EPA’s website: Emerging fuels and USTs at www.epa.gov/ust/emerging-fuels-and-underground-storage-tanks-usts

Note 3: Some owners and operators may have situations where the biofuel in the aboveground tank may not be stored for a portion of the year and/or blended to form a biofuel blended fuel being stored in the underground tanks. Owners and operators need to be aware that once the storage system is covered by the UST regulations, the storage system remains covered by the UST regulations until the storage system is permanently closed or has undergone a change-in-service. Having a portion of the storage system emptied (be in temporary closure) does not change the status of the storage system under the UST regulations. If the owner/operator has a storage system that is not (and has never been) covered by the UST regulations (for example, such as in scenario 2) but anticipates that in the future a change to the storage system will make the storage system be covered by the UST regulations (for example, such as in scenario 3), the owner/operator may choose to treat the storage system as regulated by the UST regulations prior to making the change to the storage system. If a change to a storage system makes that storage system covered by the UST regulations, the owner/operator must bring the storage system into compliance with the requirements of the UST regulations as soon as the UST regulations are applicable.

Pertinent Definition from UST regulations

The UST regulation in 40 CFR §280.12 defines underground storage tank as:

any one or combination of tanks (including underground pipes connected thereto) that is used to contain an accumulation of regulated substances, and the volume of which (including the volume of underground pipes connected thereto) is 10 percent or more beneath the surface of the ground.

This definition provides that the UST regulations are applicable to a combination of tanks where the volume of the tanks and the underground piping has 10% or more of the volume beneath the surface of the ground. This means that the UST regulations are applicable to a combination of underground and aboveground storage tanks and underground piping if at least 10% of the volume of these items is located underground. When a determination is being made as to whether the storage system is a regulated UST system, only the volume of product in underground piping is included in the storage system capacity calculation. The volume of product in aboveground piping is not included in the storage system capacity calculation.

How the UST regulations handle aboveground tanks that are part of UST systems

As noted in the section above, the UST definition includes one or a combination of tanks. Aboveground tanks can be included in an UST system, but the UST regulation in 40 CFR 280.10(c)(2) states that certain aboveground tanks be partially excluded from the regulations.

(c) Partial Exclusions. Subparts B, C, D, E, G, J, and K of this part do not apply to: …

(2) Aboveground storage tanks associated with:

(i) Airport hydrant fuel distribution systems regulated under subpart K of this part; and

(ii UST systems with field constructed tanks regulated under subpart K of this part

In the scenarios being discussed here, the UST system includes a field constructed aboveground tank, a type of tank that is partially excluded from the federal UST regulations.

In situations where the UST system includes a shop fabricated aboveground tank, the shop fabricated aboveground tank would not meet the conditions of the partial exclusion and therefore would be subject to all applicable requirements of the federal UST regulations. In addition, if the facility is subject to SPCC/FRP requirements under 40 CFR Part 112, the aboveground tank would be subject to both the UST and the SPCC/FRP requirements.

The impact of product stored on making determination of applicability of UST regulations.

The preamble to the 2015 regulations states that for a tank to be considered part of the storage system, each of the tanks would need to be storing the same product. A primary example of this is found in the discussion of airport hydrant system (Federal Register, Vol. 80, No. 135, July 15, 2015, page 41588) which states:

This final definition alleviates stakeholder uncertainty on which components of an airport hydrant system must meet the UST regulation by including all integral components that form an airport hydrant system and deliver fuel to the aircraft. These systems include underground piping and ASTs or USTs that hold aircraft fuel (for example, settling tanks or product recovery tanks). They do not include tanks or underground piping not storing aircraft fuel (for example, additive tanks) or tanks and underground piping not connected to the airport hydrant system (for example, a system that fuels an emergency power generator for a pump house).

Based on the above statement in the preamble, a tank storing jet fuel additive is not considered part of the hydrant system even though connected by piping to the hydrant system because the tank is not storing jet fuel. However, the portion of the hydrant system that contains jet fuel and the portion that contains jet fuel mixed with the additive is considered part of the same hydrant system, as the additive does not substantially change the jet fuel (therefore it is considered the same product). This determination is applicable to other storage systems where tanks are connected by piping but are not storing the same product.

Additional Resources

Additional information on the UST program is available at https://www.epa.gov/ust.

Additional information on the SPCC/FRP program is available at:

https://www.epa.gov/oil-spills-prevention-and-preparedness-regulations for program information.

https://www.ecfr.gov/current/title-40/chapter-I/subchapter-D/part-112 for regulations on the program.

https://www.ecfr.gov/current/title-40/chapter-I/subchapter-D/part-110 for discharge reporting requirements.

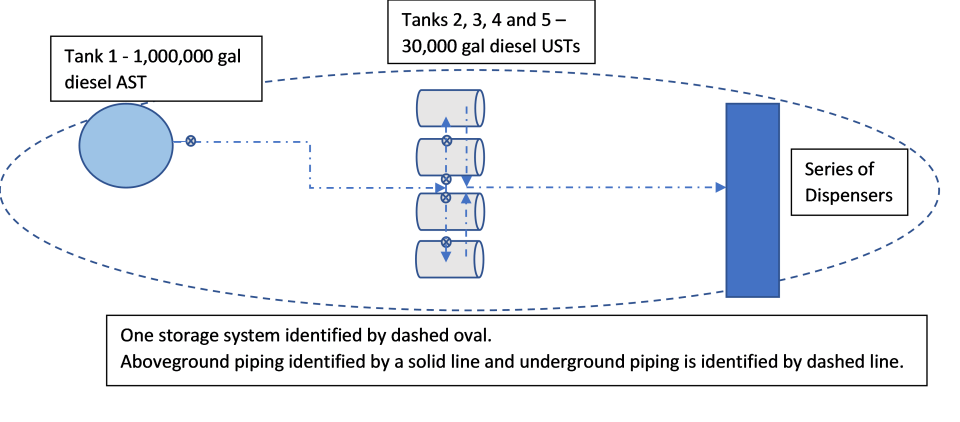

Scenario 1: If the following tanks are all storing the same product and connected by a combination of above/underground piping, is this storage system a regulated UST system?

A truck stop has the following three storage tanks connected by piping:

- Tank 1 is a 1,000,000-gallon field-constructed AST storing petroleum diesel.

- Tanks 2, 3, 4 and 5 are each 30,000-gallon USTs storing diesel.

Tank 1 is connected to tanks 2, 3, 4 and 5 by aboveground piping which transitions to underground piping at a valve. The underground piping from the valve to the tanks is 4” diameter and 853 feet long (volume is 557 gallons).

Tanks 2, 3, 4 and 5 are connected to a series of dispensers with underground piping with an estimated volume of 100 gallons.

Applicability Determination

Since these tanks are all connected and storing the same product, it is just a matter of completing the calculations to determine if there is 10% of the storage system volume underground.

% capacity underground = volume underground / volume of storage system

(120,000 gallons + 557 gallons + 100 gallons) / (1,000,000 gallons + 120,000 gallons + 557 gallons + 100 gallons

Since there is more than 10% of the volume underground, this storage system is a regulated UST system. However, the 1,000,000-gallon AST is partially excluded from the UST regulations as being a field-constructed aboveground tank associated with an UST system [40 CFR §280.10(c)(2)(ii)]. In addition, the facility 2 (including piping and tanks 3) may be subject to SPCC/FRP requirements under 40 CFR Part 112. Any aboveground piping or transfer areas (into the AST and from the dispensers) located at the facility are potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

Summary: The five tanks in Scenario #1 form one storage system that is a regulated UST system. In addition, the facility (including all aboveground piping and aboveground tanks) and transfers of product are potentially subject to SPCC/FRP requirements under 40 CFR Part 112.

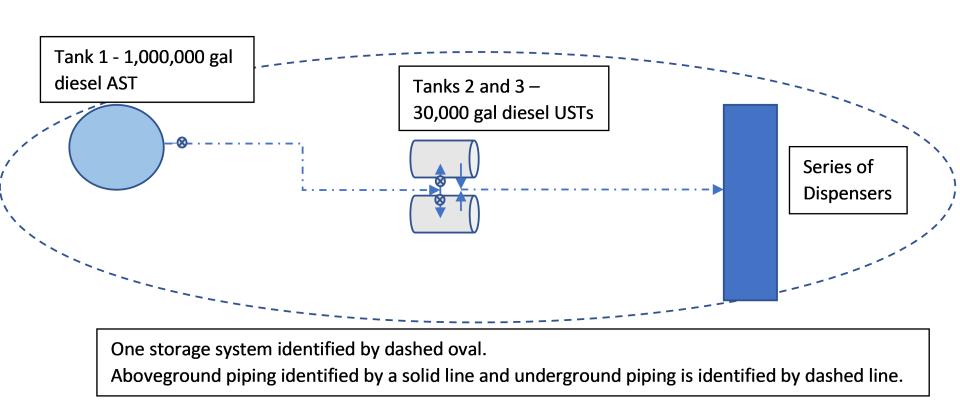

Scenario 2: If the following tanks are all storing the same product and connected by a combination of above/underground piping, is this storage system a regulated UST system?

A truck stop has the following three storage tanks connected by piping:

- Tank 1 is a 1,000,000-gallon field-constructed AST storing petroleum diesel.

- Tanks 2 and 3 are each 30,000-gallon USTs storing diesel.

Tank 1 is connected to tanks 2 and 3 by aboveground piping which transitions to underground piping at a valve. The underground piping from the valve to the tanks is 4” diameter and 853 feet long (volume is 557 gallons).

Tanks 2 and 3 are connected to a series of dispensers with underground piping with an estimated volume of 100 gallons.

Applicability Determination

Since these tanks are all connected and storing the same product, it is just a matter of completing the calculations to determine if there is 10% of the storage system volume underground.

% capacity underground = volume underground / volume of storage system

(60,000 gallons + 557 gallons + 100 gallons) / (1,000,000 gallons + 60,000 gallons + 557 gallons + 100 gallons)

Since there is less than 10% of the volume underground, this storage system is not a regulated UST system. However, the facility 4 (including all above/belowground piping and above/belowground tanks 5) may be subject to SPCC/FRP requirements under 40 CFR Part 112. Any aboveground piping or transfer areas (into the AST and from the dispensers) located at the facility are potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

Summary: The three tanks in this scenario form one storage system which is not a regulated UST system. However, the facility (including all piping and tanks) and transfers of product are potentially subject to SPCC/FRP requirements under 40 CFR Part 112.

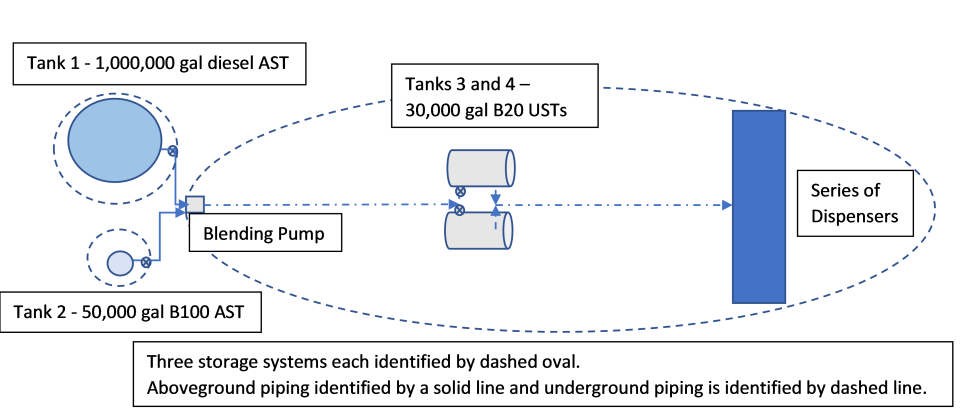

Scenario 3: Does the determination in Scenario 2 above change if there is an additional AST storing B100, an unregulated substance under 40 CFR Part 280, blending with the petroleum diesel such that the USTs are storing B20?

In this scenario the truck stop has the following four storage tanks connected by piping:

- Tank 1 is a 1,000,000-gallon field-constructed AST storing petroleum diesel.

- Tank 2 is a 50,000-gallon AST storing 100% biodiesel (B100).

- Tanks 3 and 4 are each 30,000-gallon USTs storing B20 (20% biodiesel and 80% petroleum diesel).

Tanks 1 and 2 are connected to tanks 3 and 4 by aboveground piping to the blending pump and underground piping from the blending pump to the tanks. The underground piping from the blending pump to the tanks is 4” diameter piping that is 853 feet long (volume is 557 gallons).

Tanks 3 and 4 are connected to a series of dispensers with underground piping with an estimated volume of 100 gallons.

Applicability Determination

A review of the product being stored in each of the tanks is needed to determine if they are a single storage system or if there are multiple storage systems.

- The 50,000-gallon AST storing B100 is not considered in the calculation to determine if the storage tank system is a regulated UST since B100 is not a regulated substance under 40 CFR Part 280 because it is not petroleum based, not a complex blend of hydrocarbons, and not a listed hazardous substance under CERCLA. Tanks storing B100 are not included in any UST system. However, this facility including the 50,000-gallon AST storing B100 may be subject to the 40 CFR Part 112 SPCC/FRP regulations.

- The 1,000,000-gallon AST and the two 30,000-gallon USTs are not storing the same product so there is a need to determine if the products are substantially the same or substantially different. Reviewing the American Society for Testing and Materials specifications for the products involved can help you make this determination. ASTM has identified a specification for biodiesel blends above 5 percent. Biodiesel blends at 5 percent or below have the same specification as petroleum diesel. In the scenario described above, because the underground tanks are storing B20, the product being stored in the underground tanks is substantially different than the product being stored in the 1,000,000-gallon AST. Since the products in the underground tanks are different, the 30,000-gallon USTs form their own regulated UST system because more than 10 percent of volume is underground. The facility, including the 1,000,000-gallon AST, is potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

- The underground piping from the blending pump to the USTs is included as part of the UST system. If the run of piping does not normally contain product (i.e., when the USTs are filled, the valve at the blending pump is closed but the valves at the USTs are left open such that the piping is left empty) then the piping functions like a remote fill pipe and is considered a non-operational component of the tank system. However, if the run of piping normally contains product (i.e., when the USTs are filled, the valves are closed at the USTs leaving product in the line) then the line is considered product piping and all UST technical requirements such as corrosion protection and release detection are applicable.

- Any aboveground piping or transfer areas located at the facility are potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

Summary: There are three storage systems in this scenario:

(1) 1,000,000-gallon AST storing petroleum diesel is not a regulated UST system, but the facility, including the 1,000,000-gallon AST, is potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

(2) 50,000-gallon AST storing B100 is not a regulated UST system but the facility, including the 50,000-gallon AST storing B100, is potentially subject to the 40 CFR Part 112 SPCC/FRP SPCC regulations.

(3) two 30,000-gallon USTs storing B20 (both tanks and the piping from the blending pump to the USTs, and the piping from the USTs to the dispensers) is a regulated UST system. This portion of the facility (the two 30,000-gallon USTs and buried piping) is not generally 6 subject to the requirements of 40 CFR Part 112.

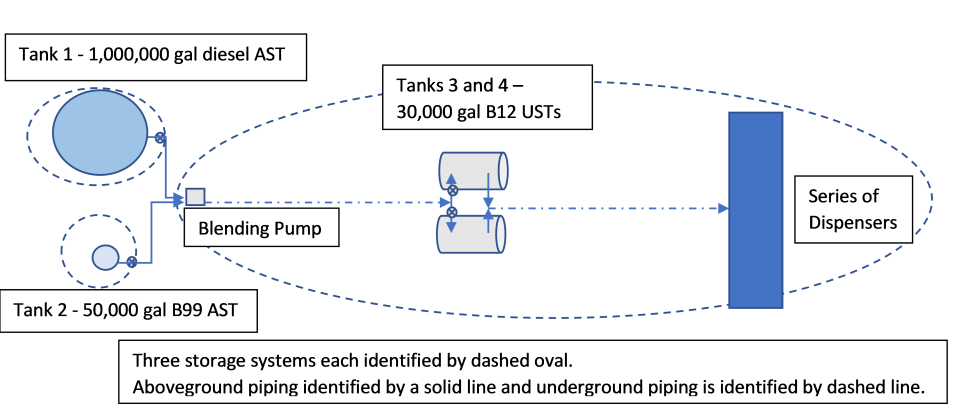

Scenario 4: Does the determination in Scenario 3 above change if the additional AST is storing B99, a regulated substance, that is blending with the petroleum diesel such that the USTs are storing B12?

In this scenario, the truck stop has the following four storage tanks connected by piping:

- Tank 1 is a 1,000,000 gallon field constructed AST storing petroleum diesel.

- Tank 2 is a 50,000 gallon AST storing 99% biodiesel and 1% petroleum diesel (B99).

- Tanks 3 and 4 are each 30,000 gallon USTs storing B12 (12% biodiesel and 88% petroleum diesel).

Tanks 1 and 2 are connected to tanks 3 and 4 by aboveground piping to the blending pump and underground piping from the blending pump to the tanks. The underground piping from the blending pump to the tanks is 4” diameter piping that is 853 feet long (volume is 557 gallons).

Tanks 3 and 4 are connected to a series of dispensers with underground piping with an estimated volume of 100 gallons.

Applicability Determination

A review of the product being stored in each of the tanks is needed to determine if they are a single storage system or if there are multiple storage systems.

- The 50,000 gallon AST storing B99 can be considered in the calculation to determine if the storage tank system is a regulated UST since B99 has 1% petroleum diesel and therefore is a regulated substance under the federal UST regulations. However, it is still a different product than what is stored in the other tanks (#3 and #4) and hence would be its own storage system. Since the B99 is being stored in an AST with no underground piping to the blending pump, less than 10% of the volume of this storage system is underground so it is not a regulated UST. The facility, including the 50,000 gallon AST storing B99 is potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

- The 1,000,000 gallon AST and the two 30,000 gallon USTs are not storing the same product with the two 30,000 gallon USTs storing a biodiesel blend of B5 or greater. Since the underground tanks are storing B12, the product being stored in the underground tanks is substantially different than the product being stored in the 1,000,000 gallon AST. Thus, the 30,000 gallon USTs form their own UST system and are regulated by the UST program. The facility, including the 1,000,000 gallon AST is potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

- The underground piping from the blending pump to the USTs is included as part of the UST system. If the run of piping does not normally contain product (i.e., when the USTs are filled, valve at the blending pump is closed but the valves at the USTs are left open such that the piping is left empty) then the piping functions like a remote fill pipe and is considered a nonoperational component of the tank system. However, if the run of piping normally contains product (i.e., when the USTs are filled, the valves are closed at the USTs leaving product in the line) then the line is considered product piping and all UST technical requirements such as corrosion protection and release detection are applicable.

- Any aboveground piping or transfer areas located at the facility are potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

Summary: There are three storage systems in this scenario:

(1) 1,000,000 gallon AST storing petroleum diesel and any aboveground piping associated with the AST are not a regulated UST system, but the facility, including the 1,000,000 gallon AST, is potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

(2) 50,000 gallon AST storing B99 is not a regulated UST system, but the facility, including the 50,000 gallon AST storing B99 and any aboveground piping associated with the AST, is potentially subject to the 40 CFR Part 112 SPCC/FRP regulations.

(3) two 30,000 gallon USTs storing B12 (both tanks and the piping from the blending pump to the USTs and the piping from the USTs to the dispensers) is a regulated UST system. This portion of the facility (the two 30,000 gallon USTs and buried piping) is not generally 7 subject to the requirements of 40 CFR Part 112.

1Spill Prevention Control and Countermeasure Rule Facility Response Plan rules, 40 CFR Part 112

2The SPCC program regulates facilities (to include tanks and piping) whereas the UST program regulates tank systems.

3For the purposes of this paper the term “tank” is being used to refer to “containers” regulated under the 40 CFR Part 112 SPCC/FRP requirements. While the field-constructed tanks and any aboveground piping can be subject to 40 CFR part 112, typically the tanks and underground piping associated with UST regulated system are exempt from the 40 CFR part 112.

4The SPCC program regulates facilities (to include tanks and piping) whereas the UST program regulates tank systems.

5For the purposes of this paper the term “tank” is being used to refer to “containers” regulated under the 40 CFR Part 112 SPCC/FRP requirements. While the field-constructed tanks and any aboveground piping can be subject to 40 CFR part 112, any underground tanks and underground piping not part of an UST regulated system, may be regulated under 40 CFR part 112.

6However, SPCC-exempt USTs subject to all the technical requirements of 40 CFR part 280/281 must be displayed on the SPCC facility diagram if the facility is required to develop and maintain a SPCC plan.

7SPCC-exempt USTs must be displayed on the SPCC facility diagram.

Implementation

Effective Dates

Question: What are the effective dates for the requirements in the 2015 UST regulation? (Added: September 2015)

Answer: Generally, most requirements take effect October 13, 2018, which is 3 years after the effective date of the 2015 UST regulation. However, some requirements take effect on October 13, 2015, which is the effective date, or April 11, 2016, which is 180 days after the effective date. For example, the changes to compatibility take effect on October 13, 2015 and the secondary containment and under-dispenser containment requirements take effect April 11, 2016.

For details about implementation time frames, see page 41570 of the Federal Register containing the 2015 UST regulations (119 pp, 1.5 MB, About PDF).

In addition, EPA developed a brochure about implementation time frames.

State Program Approval

Question: States have three years to obtain SPA or redo their SPA application. I assume that gives them 3 years to write a rule. If the operation and maintenance requirements have to be initiated within 3 years of the effective date of the rule, does that give SPA states 3 years or 6 years to start O&M requirements? (Added: September 2015)

Answer: In states without state program approval (SPA) and in Indian country, the 2015 federal requirements apply according to time frames specified in the 2015 UST regulation.

In states with SPA, none of the 2015 federal requirements apply until a state adopts the federal requirements or if a state does not adopt the federal requirements, until EPA withdraws approval of SPA for that state. Owners and operators in states with SPA must continue to meet the state UST requirements.

States with SPA have 3 years from October 13, 2015, which is the effective date of the 2015 UST regulation, to revise their regulations and submit a revised SPA application. States can give owners the same amount of time to meet the state requirements as the federal regulation gives owners to meet the federal requirements (that is, 3 years after the effective date of the state regulation.) However, EPA expects that many states will impose shorter time frames than those in the federal requirements and may even impose more stringent requirements than the federal regulation.

State Program Approval

State Program Approval and Meeting the Operator Training Requirement

Question: Where in the preamble or regulation does it state that if the state meets the operator training requirement of the statute (and not the new regulation) they do not have to change their program requirements? (Added: September 2015)

Answer: EPA agreed very early in the federal regulatory development process that we would allow states to continue to implement their state-specific operator training programs according to EPA’s Grant Guidelines To States For Implementing The Operator Training Provision Of The Energy Policy Act Of 2005, despite differences that may exist with the operator training requirements in the 2015 UST regulation.

The revised SPA regulation at 40 CFR 281.39 – Operator Training, states: “In order to be considered no less stringent than the corresponding federal requirements for operator training, the state must have an operator training program that meets the minimum requirements of Section 9010 of the Solid Waste Disposal Act.” EPA developed operator training grant guidelines that meet Section 9010 of the Solid Waste Disposal Act. As long as a state meets the grant guidelines, it will be in compliance with § 9010 and, therefore, in compliance with 40 CFR 281.39. So a state with SPA would meet the operator training requirement even if it is different from the 2015 UST regulations.

Note that in non-SPA states, both state and federal operator training requirements apply.

Spill Buckets, Under Dispenser Containment Sumps, Containment Sumps

Visual Inspections To Comply With Spill Bucket And Sump Testing Requirements

Question: Can owners and operators use ASTM E3225-20 to meet requirements of the 2015 federal UST regulation for spill bucket and sump testing in 40 CFR § 280.35(a)(1)(ii)? (Added: March 2020)

Answer: No, owners and operators cannot use this ASTM standard to meet these testing requirements (ASTM E3225-20 Standard Practice for Performing a Liquid Test of Spill Prevention Equipment and Containment Sumps Used for Interstitial Monitoring of Piping by Visual Examination). Spill prevention equipment and containment sumps used for interstitial monitoring of piping must be tested to ensure the equipment is liquid tight by using vacuum, pressure, or liquid per 40 CFR § 280.35(a)(1)(ii). ASTM E3225-20 is a visually based standard practice that does not use vacuum, pressure, nor liquid procedures.

Question: Can states or territories with state program approval (SPA) at 40 CFR 281 allow their owners and operators to use ASTM E3225-20 to meet state regulatory requirements for spill bucket and sump testing? (Added: March 2020)

Answer: No, SPA states cannot allow their owners and operators to use ASTM E3225-20 to meet testing requirements for spill bucket and sumps. In order to be considered no less stringent than the 2015 federal UST regulation, states must require spill buckets and containment sumps used for interstitial monitoring of piping be tested for integrity. A visually based inspection does not constitute an integrity test per 40 CFR § 281.32(e).

Annual Walkthrough Requirements for Sumps

Question: The federal UST regulation requires an annual inspection of containment sumps according to 40 CFR 280.36(a)(1)(ii)(A). Does this include sump areas, that is the tank top and under dispenser areas, that:

- Are not used for interstitial monitoring; or

- Are only partially contained without bottoms; or

- Have no containment at all, with only dirt surrounding the submersible turbine pump (STP) or under the dispenser? (Added: April 2018)

Answer: Yes, the annual walkthrough inspection requirement generally applies to all operational sump areas. However, not all the specific requirements of the annual inspection are always applicable in each of those scenarios.

The specific requirements of the annual inspection according to 40 CFR 280.36(a)(1)(ii)(A) are to:

- Visually check for

- damage

- leaks to the containment area

- releases to the environment.

- Remove liquid or debris.

- For double-walled sumps with interstitial monitoring, check for a leak in the interstitial area.

So, for example, in a scenario where the STP or under dispenser areas have only partial containment sumps or no containment at all, removing liquid is not typically applicable; 40 CFR 280.36(a)(1)(ii)(A) indicates in contained sumps only.

Similarly, visually checking for damage does not typically apply directly to sump walls themselves when the sump is not used for interstitial monitoring because the function of the sump is not release detection. In those situations, an owner or operator is only required to visually check for damage to the proper operating condition of the equipment within the sump area, for example significant corrosion affecting proper STP operation, not necessarily to the sump or partial sump itself.

For containment sumps used for interstitial monitoring, the visual check applies directly to the sump itself. In those cases, the proper operating condition of the sump is to contain regulated substances and, therefore, the visual check is for any damage that makes the sump unable to contain regulated substances and not be liquid tight. The specific requirements to record and repair damage to containment sump tightness may vary depending on the operation and maintenance walkthrough inspection requirements of the implementing agency. For example, some states may require repair to achieve containment sump tightness up to or above the highest penetration point of the sump so that it meets the Petroleum Equipment Institute's (PEI) RP 1200-17 spill bucket and containment sump testing section 6 standards. EPA’s UST technical compendium discusses an example of low level sump testing under 40 CFR 280.35(a)(1)(ii)(C). In this example, EPA considers repair to achieve containment sump tightness to at least the height where a liquid level sensor will activate to be no less protective under 40 CFR 280.35(a)(1)(ii)(C).

Owners and operators in state program approval (SPA) states should check with their implementing agencies to determine applicable requirements, which may vary from EPA's determination in this area; see 40 CFR 281.32(f) General Operating Requirements.

Spill Bucket Testing on Stage I Vapor Recovery Lines

Question: If an owner has spill containment buckets installed on the Stage I fittings on the UST systems, would those be required to be tested every 3 years as well (or monitored monthly)? Or would they not require a test because they are not attached to the tank fill? (Added: September 2015)

Answer: 40 CFR part 280.20(c)(1)(i) only requires spill prevention equipment where the transfer hose is detached from the fill pipe. There is no requirement in the 2015 UST regulation for containment around a Stage I vapor recovery port. While it would be prudent to test any containment around the vapor recovery port, the 2015 UST regulation does not require owners and operators to perform this testing since the containment is not required by the UST regulation. Please note that the 2015 UST regulation requires testing of the containment if both the fill pipe and vapor recovery port are located in a single containment area.

Note that state UST programs may have more stringent requirements and may require testing of containment around Stage I vapor recovery ports.

Testing of Double-Walled Spill Buckets and Double-Walled Containment Sumps

Question: Are tank owners required to test at least once every three years double-walled spill buckets and containment sumps used for interstitial monitoring, if the interstitial space is periodically monitored and found to have integrity? (Added: September 2015; Modified November 2017)

Answer: Testing once every three years is not required if the integrity of both walls of a double-walled spill bucket or containment sump is periodically monitored. Owners and operators who check vacuum, pressure, or liquid interstitial integrity indicators on spill buckets at least every 30 days and containment sumps at least annually are considered to be periodically monitoring the integrity of both walls; see 40 CFR 280.35(a)(1)(i) and 280.36.

Every three years, owners and operators must test double-walled spill buckets and containment sumps if they choose not to periodically monitor the integrity of both walls; see 40 CFR 280.35(a)(1)(ii). Typically, a sensor in a dry interstice does not meet the requirement to periodically monitor the integrity of both walls. That means testing is required at least every three years for double-walled spill buckets and containment sumps with a sensor in a dry interstice.

According to 40 CFR 280.35(a)(1)(ii) A, B, or C, testing the interstice of spill buckets and containment sumps satisfies the every three year testing requirement if it is done according to:

- A code of practice developed by a nationally recognized association or independent testing laboratory, or

- Requirements developed by the manufacturer, or

- Requirements determined by the implementing agency to be no less protective of human health and the environment.

Owners and operators in State Program Approval (SPA) states should check with their UST implementing agencies to determine applicable requirements, which may vary from EPA's determination in this area; see 40 CFR 281.32(e) General Operating Requirements.

Containment Sump – Liquid Tightness

Question: EPA states that both new and existing containment sumps, when used for interstitial monitoring must be liquid tight. Does EPA require that containment sumps and under-dispenser containment (UDC) sumps be liquid tight on top, regardless of whether they have a lid or other cover? (Added: September 2015)

Answer: For UDC, the 2015 UST regulation at 40 CFR 280.20(f)(2) indicate that UDC must be liquid tight on its sides, bottom, and at any penetrations. This section does not indicate that UDC must be liquid tight on top.

For other containment sumps, 40 CFR 280.35(a)(1)(ii) indicates that the containment sump must be tested once every 3 years to ensure the equipment is liquid tight. There are no further details in the 2015 UST regulation for containment sump testing. Using a liquid test method to test a containment sump does not test the top or lid of the containment. In a vacuum test method, typically the lids are removed during the test.

Based on this information, EPA does not think containment sumps must be liquid tight on top, whether or not they have a lid or other cover.

Containment Sump – Dispenser Replacement and Under-Dispenser Containment Installation Requirements

Question: Are tank owners required to install UDC if only several components of the dispenser system are replaced, but not the entire dispenser system (for example a shear valve but not flexible connectors)? Or, are tank owners required to install UDC if any single component of the dispenser system is replaced? (Added: September 2015)

Answer: The 2015 UST regulation at 40 CFR 280.20(f) indicates that a dispenser system is considered new when both the dispenser and the equipment needed to connect the dispenser to the underground storage tank system are installed. That equipment may include check valves, shear valves, unburied risers or flexible connectors, or other transitional components that connect the dispenser to the underground piping. This means that the UDC requirement is not triggered until the dispenser and everything between the dispenser and the underground piping is installed.

Note that most states have already implemented their own requirements for secondary containment and UDC. The 2015 UST regulation primarily applies to owners and operators of UST systems in Indian country.

Containment Sump – UDC Installation with Sensor Monitoring

Question: Will the replacement of a dispenser at a site trigger the need to add an under-dispenser containment sump and sensor monitoring? (Added: December 2015)

Answer: If an existing dispenser and the equipment used to connect the dispenser to the underground piping are removed and replaced with a new dispenser, then under-dispenser containment is required for that dispenser; see 40 CFR 280.20(f).

EPA does not require owners and operators to add sensors for monitoring under-dispenser containment when UDC is required. Owners and operators may need to add sensors to UDC areas to meet the periodic monitoring requirement for sumps that cannot be visually inspected or to meet the piping interstitial monitoring requirement when piping is installed or replaced after April 11, 2016; see 40 CFR 280.20(f)(2).

Containment Sump – UDC Testing

Question: Are tank owners required to test all UDC or only UDC used for both secondary containment and interstitial monitoring of pipes? (Added: September 2015)

Answer: Periodic testing of containment sumps, including UDC, is required only when the containment sump is used for secondary containment of the piping and interstitial monitoring is used for release detection of that piping. The location of the interstitial monitoring device is not a factor in determining whether periodic testing is required. For example, owners and operators have UDC that is used as the secondary containment for piping where regulated substances can drain to another sump that is monitored with a sensor. In this case, UDC must meet the periodic testing requirement because it is used as part of secondary containment and interstitial monitoring of the piping.

Containment Sump – Testing for Systems with Double-Walled Piping

Question: Is containment sump testing required for double-walled piping systems that use sump sensors as a good management practice but rely on a method other than interstitial monitoring to meet the piping release detection requirement? (Added: December 2015)

Answer: No. The 2015 UST regulation does not require containment sump testing if the release detection method for the piping is something other than interstitial monitoring.

While EPA does not require this testing, some states may treat redundant release detection systems differently. Owners and operators should check with their UST implementing agencies to determine applicable requirements.

Containment Sump – Testing for Systems with Double-Walled Piping – Open and Closed to the UDC

Question: Do UDC sumps need to be tested once every 3 years if the double-walled piping is closed to the sump (i.e., the piping is double-walled throughout the dispenser and the containment sump is not used as part of the secondary containment of the piping)? (Added: September 2015)

Answer: The requirement to test sumps, or have double-walled sumps with periodic monitoring, hinges on whether that sump is used as part of the piping secondary containment when interstitial monitoring is used as release detection for the piping. The requirement to test the sump is independent of whether the sump is open or closed or whether sensors reside in that sump or somewhere else. And it applies to any containment sump used for piping interstitial monitoring, independent of whether the containment sump is old or new.

Any sump used as part of the secondary containment system that is interstitially monitored must either be double-walled with periodic monitoring of the space between the sump walls or be tested once every 3 years.

Question: If the double-walled piping is open under the dispenser allowing a leak to drain into the dispenser sump or the submersible turbine pump (STP) sump, then do the UDC sumps and the STP sump have to be tested once every 3 years? (Added: September 2015)

Answer: For the question about closed piping under dispensers, in this case, the under-dispenser containment does not need to be tested because the UDC is not part of the piping secondary containment where interstitial monitoring is used.

If the outer wall of the double-walled piping is open in the UDC, or ends at the UDC wall, then the UDC would be considered secondary containment for the single-walled piping in the UDC, independent of whether the UDC was open or closed to the STP sump. In this case, the UDC is part of the secondary containment and interstitial monitoring for the piping, and therefore would have to be tested once every 3 years, or be double-walled with periodic monitoring of the space between the walls.

Containment Sump – Testing for Systems with Single-Walled Piping

Question: Suppose there is single-walled piping in a UDC sump leading up to the dispenser, below the shear valve, and the single-walled piping is connected by single-walled flex connector to double-walled piping.

Does the single-walled piping have to meet the secondary containment and interstitial monitoring requirement?

Does the UDC have to meet the 3-year testing requirement? (Added: March 2017)

Answer: Yes, to both questions. According to the 2015 federal UST regulation, all piping installed or replaced after April 11, 2016 must meet the secondary containment and interstitial monitoring requirement. EPA considers the UDC as secondary containment for the single-walled piping, including the single-walled flex connector, beneath the shear valve. According to 40 CFR 280.43(g), owners must monitor the UDC by interstitial monitoring as the primary method of release detection.

In this case, the UDC is part of the secondary containment and interstitial monitoring for the single-walled piping; it must be tested once every 3 years or be double-walled with periodic monitoring of the space between the walls.

Note that most states have already implemented their own requirements for secondary containment and UDC. The 2015 federal UST regulation primarily applies to owners and operators in Indian country.

Containment Sump – Test Procedures

Question: What procedures can be used to test single-walled containment sumps? Is there a procedure that tests containment sumps, does not require filling the containment sump with water to 4 inches higher than the highest penetration in the sump, and is acceptable to EPA? (Added: May 2017; Modified June 2018; Modified March 2020)

Regulatory requirement

Unless the sump is double-walled and the integrity of both walls is periodically monitored, 40 CFR 280.35(a)(1)(ii) requires containment sumps used for interstitial monitoring of piping be tested at least once every three years to ensure the equipment is liquid tight by using vacuum, pressure, or liquid testing. Options for conducting the test include: (A) requirements developed by the manufacturer, (B) a code of practice developed by a nationally recognized association or independent testing laboratory, (C) requirements developed by the implementing agency determined to be no less protective of human health and the environment than (A) or (B).

Answer: As noted above, EPA allows three options for testing containment sumps, also referred to as sumps. Below is information about each option.

Requirements Developed By Sump Manufacturer

EPA is not aware of any manufacturers of single-walled containment sumps who provide procedures on how to test their sumps.

Code Of Practice

EPA is aware of only one code of practice that provides procedures to test a sump using vacuum, pressure, or liquid. That code of practice is Petroleum Equipment Institute Recommended Practice (PEI RP) 1200-19, which provides two procedures for testing containment sumps. The original procedure requires testing the sump by filling it with water to 4 inches above the highest penetration. In 2019, PEI updated RP 1200 to provide another procedure for testing the sump at a lower liquid level if certain conditions are met. Since both procedures are contained within a code of practice developed by a nationally recognized association and the procedures test the sump hydrostatically, EPA determined these testing procedures are acceptable to meet the requirement to test the containment sump for liquid tightness.

Alternative Test Procedures – EPA Low Liquid Level Testing

Before PEI revised RP 1200 to include a low liquid level testing procedure, EPA was aware that in some situations, such as for certain older systems, testing to 4 inches above the highest penetration may create unusual challenges and unintended consequences. These include:

- It could be difficult to access the sump, requiring the dispenser be removed in order to do the testing.

- The challenges and costs of testing above penetration fittings may lead some owners to abandon their interstitial monitoring and move to a different and possibly less protective release detection method.

- The increased costs incurred for testing to the higher level may serve as a disincentive for owners to upgrade existing systems to include double-walled piping with interstitial monitoring and containment sumps.

While testing to a level less than 4 inches above the highest penetration may be less protective than testing at a higher liquid level, if included with conditions similar to those specified in PEI RP 1200, the implementing agency may be able to determine that testing at a lower level is as protective as testing at a higher liquid level. This example discusses what EPA considers to be no less protective under 40 CFR 280.35(a)(1)(ii)(C).

Example

- A liquid level sensor is mounted at the lowest point in the sump and a periodic test is performed by adding liquid to a point that will ensure activation of the sensor; and

- The pump automatically shuts off when liquid activates the sensor, or

- The dispenser automatically shuts off when liquid activates the sensor, and the facility is always staffed when the pumps are operational.

Low Liquid Level UST Containment Sump Testing Procedures for conducting this alternate test at facilities where EPA is the implementing agency.

Additional Alternative Test Procedures

In addition, EPA is aware of other containment sump testing procedures that are not provided by the sump manufacturer and are not incorporated into a code of practice. Nevertheless, these procedures test the liquid tightness of the sump using vacuum, pressure, or liquid.

EPA determined sump tests meeting the criteria below are no less protective of human health and the environment under 40 CFR 280.35(a)(1)(ii)(C). It is acceptable to use them for sump tests in instances when EPA is the implementing agency.

- The sump is tested for liquid tightness using vacuum, pressure, or liquid.

- Equipment and procedures for the sump test can detect a leak of 0.1 gallons per hour with a probability of detection of at least 95 percent with a probability of false alarm of no more than 5 percent.

- The test method has been evaluated by an independent testing laboratory, consulting firm, not-for-profit research organization, or education institution using an applicable test procedure developed by EPA, and the test procedure is appropriate for the type of release detection technology being evaluated. You may obtain the test procedures at EPA’s underground storage tank website www.epa.gov/ust/standard-test-procedures-evaluating-various-leak-detection-methods.

To demonstrate their sump test meets the above criteria, manufacturers may request the National Work Group on Leak Detection Evaluation (NWGLDE) review their evaluation. NWGLDE lists those sump tests that meet the criteria; see Secondary and Spill Containment Test Methods at: https://neiwpcc.org/nwglde/by-testing-method/secondary-and-spill-containment-test-methods/.

UST Sump Test Water Characterization and Disposal

Question: Because petroleum constituents may be present, is the used test water considered a hazardous waste under 40 CFR Part 261, Identification and Listing of Hazardous Waste, (RCRA Subtitle C)? (Added: May 2017)

Answer: Under the Resource Conservation and Recovery Act (RCRA), Subtitle C, a material must first be a solid waste as described under 40 CFR 261.2 before it can be a hazardous waste. As long as the test water is suitable for reuse and is continuing to be reused, it is not considered a waste. When it is to be disposed, it becomes a solid waste and must be evaluated to determine whether it is a hazardous waste.

Once the sump test water will be disposed, the test water will be a hazardous waste if it exhibits any of the characteristics of hazardous waste described in 40 CFR 261.21-24. With the test water, the most likely characteristics that could apply are the toxicity characteristic (TC) in 40 CFR 261.24 and ignitability characteristic in 40 CFR 261.21.

- Toxicity characteristic: The chemical benzene, often found in petroleum products, is the constituent most likely to be found in UST sump test water in concentrations equal to or greater than the TC regulatory value, which for benzene is 0.5 mg/l. Thus approximately 0.007 ounces of benzene in 100 gallons of test water would exceed the TC limit. Note: The water solubility of benzene at 23.5 degrees C is 0.188 percent, or 1880 ppm. While gasoline has typically contained approximately 1 percent benzene, in 2011 EPA required benzene to be limited to 0.62 percent; see entry 1094 of the Merck Index, 12th Ed., 1996, and Gasoline Mobile Source Air Toxics.

- Ignitability characteristic: If a representative sample of the sump test water exhibits a flash point below 140 degrees F at the point of generation or during the course of its management, it would be an ignitable hazardous waste. Note: Pure benzene has a closed cup flash point of 12 degrees F; see entry 1094 of the Merck Index, 12th Ed., 1996.

- Gasoline is more likely than diesel fuel, kerosene, or heating oil to be hazardous for benzene or flash point. Kerosene has a flash point of 150-185 degrees F; see entry 5305, Merck Index, 12th Ed, 1996.

Question: What procedures can be used to determine if the test water is hazardous waste under RCRA Subtitle C? (Added: May 2017)

Answer: 40 CFR 262.11, Standards Applicable to Generators of Hazardous Waste, requires generators to employ one of two procedures to determine whether a solid waste is a hazardous waste:

- Analytical testing: With respect to the sump test water, the relevant tests for benzene are: EPA Method 1311/8260 or 1311/5030/8015 or 1311/5030/8021 to determine if there is enough benzene in the test water that it fails for toxicity, and EPA Methods 1010A or 1020B to determine if the test water fails for ignitability. Toxicity characteristic leaching procedure, or TCLP, is the method used for determining whether a waste exhibits the toxicity characteristic; see 40 CFR 262.11. Note the TCLP test considers the solids content of the test water. More information about these laboratory test methods are available in EPA’s SW-846 Compendium.

- Generator knowledge: Generators may apply knowledge of the hazard characteristics of the waste in light of the materials or the process used to generate the waste. The key to using a knowledge of process is that it should be scientifically defensible and capable of reliably and accurately determining whether the waste is hazardous, particularly for non-hazardous determinations. Because only a very small amount of benzene needs to be present in order for the test water to be TC hazardous (approximately 0.007 ounces of benzene in 100 gallons of water), a knowledge of process evaluation is in all likelihood incapable of ascertaining that the test water is non-hazardous, but it certainly could be used to determine the water to be hazardous (based on the water solubility of benzene and its presence in gasoline). Appropriate knowledge of materials and process for a waste stream like the test water could include information such as:

- The process that generated the waste (that is, the fact that this process brings water into contact with gasoline, which contains benzene).

- Observation of visible free petroleum in the test water, since the test water is likely to fail analytical testing if visible petroleum is present.

- Past sampling results of prior test water generated under similar conditions.

- Basic physical and chemical knowledge about likely waste constituents.

Question: Is the test water exempt from the hazardous waste requirements via the exemption in 40 CFR 261.4 (b)(10)? This exemption states that the following solid wastes are not hazardous wastes:

40 CFR 261.4(b)(10): “Petroleum-contaminated media and debris that fail the test for the Toxicity Characteristic of §261.24 (Hazardous Waste Codes D018 through D043 only) and are subject to the corrective action regulations under part 280 of this chapter.” (Added: May 2017)

Answer: The test water does not qualify for this exemption from the hazardous waste requirement for several reasons. First, the test water is not consistent with the term media or debris as defined in 40 CFR 261 and 268.2(g). That is, the water being discarded has been used as a product for testing sump integrity and is not ambient media that has been contaminated by an outside source. Second, even if it were media or debris that fails the toxicity characteristics of 40 CFR 261.24, the test water is not subject to the corrective action regulation under 40 CFR 280. Water used to test multiple sumps may pick up petroleum constituents but would not generally require reporting under the UST regulation, unless there is an indication of a release from the UST system. Therefore, sump test water does not meet the requirements for the exemption. Federal Register, Vol 58, No 28 (332 pp, 83 MB, About PDF).

Question: Is the test water exempt from the hazardous waste requirements if it is sent for reclamation per 40 CFR 261.2(c)(3)? (Added: May 2017)

Answer: The regulation at 40 CFR 261.2(c)(3) exempts from regulation off-specification commercial chemical products that are legitimately reclaimed to produce fuels. EPA has interpreted this exemption to include off-specification fuel materials such as fuel and water mixtures in a November 2016 letter (2 pp, 390K, About PDF).

This exemption could apply to the test water, if the test water contains enough fuel such that fuel could be legitimately reclaimed if the test water is sent to a fuel recycling facility for recovery.

Question: If the water is reused multiple times and transferred from one sump to another, when does a hazardous characterization have to occur? (Added: May 2017)

Answer: If the testing contractor or UST facility owner and operator can and does reuse the test water to perform testing at another facility, then the test water is not a waste at that point. A testing contractor or UST facility owner and operator could potentially reuse the water over and over again, especially if the test water is filtered in between uses to remove any free or dissolved petroleum. When the tester decides not to reuse the water, it then becomes a waste, must be characterized, and either properly disposed or determined if it can be reclaimed as discussed in question above about reclamation.

Question: If the test water is characterized as hazardous waste, how must it be properly managed? (Added: May 2017)

Answer: Possible options include legitimate reclamation of the test water or disposing of it according to prescribed RCRA regulations.

- See question and answer above for possible reclamation options.

- Possible disposal options include:

- If the test water is not ignitable, it may be acceptable to dispose of it via the sanitary sewer. Approval from the local sewer authority is generally required and it is highly recommended that you check with your state, tribal, and local authorities for rules or other restrictions regarding such a disposal method.

- You may drum and store the test water properly until a hazardous waste hauler picks it up according to the hazardous waste generator regulations which specify accumulation time and management standards depending on how much hazardous waste is generated in a calendar month; see EPA's hazardous waste generator website for more info. Check with your state, tribal, and local authorities for the applicable requirements for hazardous waste stored on site by generators and also to determine if there are licensing requirements for hazardous waste haulers in your jurisdiction.

- You may filter the test water through an oil-water separator and properly dispose of the oil and water. Check with your state, tribal, and local authorities for requirements regarding disposal of the oil and water from the oil-water separator. It is possible that even after the water is filtered, it may contain enough benzene to be considered hazardous waste.

Question: If the test water is not characterized as being a hazardous waste, how can it be properly disposed? (Added: May 2017)

Answer: Even where the water is non-hazardous under the RCRA regulations, the testing contractor or UST facility owner and operator should check with state, tribal, and local authorities regarding applicable requirements for disposal, including disposal to the sanitary sewer or other safe waste management practice.

Question: Who becomes the generator for the test water when it is no longer usable and becomes a waste? (Added: May 2017)

Answer: This depends on when and where the test water becomes a waste. If the test water is used just once prior to being disposed, then the facility where the test is conducted is the generation site. Under the RCRA hazardous waste generator requirements, where more than one party’s actions contribute to a waste being generated, all parties are subject to joint and several liability as generators – they are co-generators. For example, the testing contractor is a generator under 40 CFR 262.10 because his actions produce the waste test water, and the owner and operator of the facility is a generator because they own the equipment from which the waste is generated. Joint and several liability dictates that both generators are responsible for ensuring compliance with applicable hazardous waste requirements. However, EPA prefers and even encourages one party to assume and perform the duties and responsibilities of generator on behalf of all parties, as appropriate. EPA recommends that co-generators specify via a contract who is responsible for compliance with hazardous waste and disposal requirements.

Question: What if it is not determined whether the test water will be reused until after the test water is returned to the testing contractor’s home site? (Added: May 2017)

Answer: If the test water is returned to the testing contractor’s home site and it is then determined the test water will not be reused, the testing contractor is the sole generator and solely responsible for evaluating and properly managing the waste.

For additional information, see EPA’s Waste Analysis at Facilities that Generate, Treat, Store and Dispose of Hazardous Waste – Final: A Guidance Manual.

Tank Collars Connected to Sumps

Question: When using a double-walled sump with interstitial monitoring, does the collar connecting the sump to the tank top surface also have to be double-walled? (Added: December 2017)

Answer: Yes; the collar connecting the sump to the tank top surface has to be double-walled. The interstice or interstitial communication must be continuous for the entire containment area.

Spill Prevention Equipment for UST Systems that are not airport hydrant systems or UST systems associated with field-constructed tanks

Question: Does the installation of a concrete berm around the fill pipe for spill prevention equipment meet the requirements for proper installation for an UST system that is not an airport hydrant system (AHS) or UST systems associated with field-constructed tanks (FCT) and is installed after December 22, 1988, requiring that the installation must be performed in accordance with a code of practice developed by a nationally recognized association or independent testing laboratory?

Answer: Owners and operators in states with UST state program approval (SPA) should check their state UST agency, whose guidance may vary from EPA's determination in this area.

For owners and operators where 40 CFR Part 280 is applicable (i.e., USTs located in Indian Country and in states without state program approval), if the UST system is not an AHS or associated with FCT, an owner/operator who uses a concrete berm around the fill pipe to meet the spill prevention equipment requirement may meet the requirements for proper installation if one of the conditions for installation below is true.

Regulatory Requirements for Spill Prevention:

40 CFR 280.20(c)(1)(i) requires that owners and operators use the following spill prevention equipment:

(i) Spill prevention equipment that will prevent release of product to the environment when the transfer hose is detached from the fill pipe (for example, a spill catchment basin).

In addition, for UST systems installed after December 22, 1988, 40 CFR 280.20(d) requires:

(d) Installation. The UST system must be properly installed in accordance with a code of practice developed by a nationally recognized association or independent testing laboratory and in accordance with the manufacturer's instructions.

And

(e) Certification of installation. All owners and operators must ensure that one or more of the following methods of certification, testing, or inspection is used to demonstrate compliance with paragraph (d) of this section by providing a certification of compliance on the UST notification form in accordance with § 280.22….

(6) The owner and operator have complied with another method for ensuring compliance with paragraph (d) of this section that is determined by the implementing agency to be no less protective of human health and the environment.

Installation Requirements:

One of the following requirements must be met:

- The UST system was installed in accordance with a code of practice developed by a nationally recognized association or independent testing laboratory that provides information/specifications for the installation of the concrete berm around the fill pipe. The owner/operator must maintain documentation of this code of practice for as long as the concrete berm is used to meet the spill prevention equipment requirement. (Note: EPA is not aware of any current code of practice that provides this information/specification, but codes of practices have been modified over time; therefore, there may have been a code of practice at the time the UST system was installed that provided this information/specification.)

- The implementing agency has determined that the installation of the concrete berm is no less protective of human health and the environment than installing spill prevention equipment, in accordance with a code of practice developed by a nationally recognized association or independent testing laboratory. The implementing agency has determined that another regulation that requires the installation of a concrete berm has conditions to ensure that the berm is properly installed by either review and sign-off by a professional engineer or the regulations sets requirements for proper installation. In addition, the concrete berm area meets the conditions listed in Conditions for concrete berm to meet spill prevention requirements (see below) in the answer to the question below; or

- The implementing agency has determined that the installation of the concrete berm is acceptable because the owner/operator has demonstrated that the concrete berm around the fill pipe has been installed so that it is no less protective of human health and the environment than installing spill prevention equipment, in accordance with a code of practice developed by a nationally recognized association or independent testing laboratory. This demonstration may come in the form of the installation of the concrete berm inspected and certified by a registered professional engineer with education and experience in concrete installation.

Question: When an UST system is not an AHS or associated with FCT, what conditions need to be considered to determine that a concrete berm around a fill pipe meets the spill prevention requirement to “prevent release of product to the environment when the transfer hose is detached from the fill pipe?” (from 40 CFR 280.20(c)(1)(i)).

Answer: Owners and operators in states with UST state program approval (SPA) should check their state UST agency, whose guidance may vary from EPA's determination in this area.

Where 40 CFR Part 280 is applicable (i.e., USTs located in Indian Country and in states without state program approval) and the UST system is not an AHS or associated with FCT, EPA would generally consider the conditions listed below to determine if the concrete berm will prevent releases to the environment when the transfer hose is detached from the fill pipe.

Conditions for concrete berm to meet spill prevention requirements

- The connection point for the transfer hose to the fill port is inside the concrete bermed area in a location that would not allow for the release of product to the environment when the hose is detached from the fill pipe

AND

- The concrete bermed area will contain any product spilled when the hose is disconnected. This means the concrete bermed area must have integrity (i.e., no holes or pathways for any spilled product to be released to the environment).

Note about oil water separators: If the concrete bermed area normally drains to an oil water separator, then the drain to the oil water separator needs to be closed or blocked off while a delivery is being made, so that any spill of product will be contained in the bermed area. Inability to close or block this pathway precludes the bermed area from meeting the requirement to have integrity required under this condition.

EPA believes the two conditions above are sufficient to determine that the concrete berm around a fill pipe meets the requirement to “prevent release of product to the environment when the transfer hose is detached from the fill pipe,” when combined with the following requirements from 40 CFR Part 280:

- The concrete bermed area is proven to prevent releases of product by being tested for liquid tightness in accordance with a code of practice as required by 40 CFR 280.35(a)(1). Owners and operators may use the procedures provided in PEI RP 1200 Recommended Practices for the Testing and Verification of Spill, Overfill, Leak Detection and Secondary Containment Equipment at UST Facilities or UFC 3-460-03 O&M: Maintenance Of Petroleum Systems, With Change 1. (See information in Testing Procedures for Spill Prevention Equipment for airport hydrant systems and UST systems associated with field-constructed tanks.)

- The concrete bermed area will be properly maintained through visual inspection for damage every 30 days (unless receiving deliveries at intervals greater than 30 days, in which case the visual check must be conducted prior to each delivery) as required by the monthly walkthrough inspection and records kept on actions taken to correct any issues (40 CFR 280.36).

UST systems may be located at a facility that is also otherwise regulated under the SPCC program (40 CFR Part 112). For example, the facility may have an aboveground storage tank (containers) associated with the UST system, or a facility may have other containers that trigger the SPCC applicability thresholds. Facilities that are regulated under the SPCC program are also required to provide secondary containment at any transfer area and/or any loading rack area including those associated with the UST system.

The SPCC requirements for oil transfer operations associated with USTs at otherwise SPCC regulated facilities which are not occurring at a loading rack include:

- General containment requirements for loading/unloading areas in accordance with 40 CFR 112.7(c)

The SPCC requirements for oil transfer operations associated with USTs at otherwise SPCC regulated facilities which occur at a loading rack include:

- Specific sized secondary containment in accordance with 40 CFR 112.7(h)(1);

- Interlocked warning light or physical barrier system, warning signs, wheel chocks or vehicle brake interlock system in the area adjacent to a loading/unloading rack, to prevent vehicles from departing before complete disconnection of flexible or fixed oil transfer lines containment in accordance with provisions in 40 CFR 112.7(h)(2) and;

- Inspection of any tank car or tank truck located at the loading rack prior to filling and departure of any tank car or tank truck containment in accordance with provisions in 40 CFR 112.7(h)(3).

Owners and operators of UST systems that meet the requirement of 40 CFR 112.7(c) or 112.7(h)(1) with passive1 secondary containment which meet the conditions listed above in Conditions for concrete berm to meet spill prevention requirements meet the spill prevention equipment requirement of 40 CFR 280.20(c)(1).