Frequent Questions About Underground Storage Tanks

EPA is providing answers to the following questions. These questions and answers are not intended to be a substitute for the written underground storage tank regulations. For a complete description of the regulations, refer to the Code of Federal Regulations, 40 CFR Part 280. In addition, you can find additional answers to technical questions in the UST Technical Compendium. Also, Program Facts presents a brief overview about the UST program and some basic facts that are updated periodically.

On this page:

- General

- What is an underground storage tank (UST) system?

- What is the history of the federal underground storage tank program?

- Who can answer questions about UST systems?

- Why are UST systems regulated?

- Who regulates UST systems?

- What are the responsibilities of an UST owner or operator?

- What are my reporting responsibilities as an owner or operator?

- Are heating oil tanks regulated?

- What are the requirements for hazardous substance USTs?

- Are aboveground storage tanks regulated?

- How many UST systems have leaked? How many have been cleaned up?

- How are UST systems that were deferred in the 1988 UST regulation handled today?

- Prevention

- Cleanup

General

What is an underground storage tank (UST) system?

An underground storage tank (UST) system is a tank (or a combination of tanks) and connected underground piping having at least 10 percent of their combined volume underground. The tank system includes the tank, underground connected piping, underground ancillary equipment, and any containment system. The federal UST regulations apply only to UST systems storing either petroleum or certain hazardous substances.

The following types of tanks do not have to meet federal UST regulations:

- Farm and residential tanks of 1,100 gallons or less capacity holding motor fuel used for noncommercial purposes

- Tanks storing heating oil used on the premises where it is stored

- Tanks on or above the floor of underground areas, such as basements or tunnels

- Septic tanks and systems for collecting storm water and wastewater

- Flow-through process tanks

- UST systems of 110 gallons or less capacity

- Emergency spill and overfill tanks

However, some implementing agencies may include these tank types in their UST regulations. Be sure you check with these authorities if you have questions about the requirements for your tank type.

Other storage sites, such as surface impoundments, pits, ponds, or lagoons are not covered by the federal requirements.

For more detailed information on the applicability of federal UST requirements for different types of USTs, please refer to Subpart A of Part 280 of the Code of Federal Regulations.

What is the history of the federal underground storage tank program?

Until the mid-1980s most underground storage tanks (USTs) were made of bare steel, which is likely to corrode over time and allow UST contents to leak into the environment. The greatest potential hazard from a leaking UST is that its contents (petroleum or other hazardous substances) can seep into the soil and contaminate ground water, the source of drinking water for nearly half of all Americans.

To address a nationwide problem of leaking USTs, Congress passed a series of laws to protect human health and the environment.

1984

Subtitle I was added to the Solid Waste Disposal Act through the Hazardous and Solid Waste Amendments

- Created a federal program to regulate USTs containing petroleum and hazardous chemicals to limit corrosion and structural defects and thus minimize future tank leaks

- Directed EPA to set operating requirements and technical standards for tank design and installation, leak detection, spill and overfill control, corrective action, and tank closure

1986

Subtitle I was amended through the Superfund Amendments Reauthorization Act

- Authorized EPA to respond to petroleum spills and leaks

- Directed EPA to establish financial responsibility requirements for UST owners and operators to cover the cost of taking corrective actions and to compensate third parties for injury and property damage caused by leaking tanks

- Created a Leaking Underground Storage Tank (LUST) Trust Fund

The Fund is used to oversee cleanups by responsible parties, enforce cleanups by recalcitrant parties, and pay for cleanups at sites where the owner or operator is unknown, unwilling, or unable to respond, or where emergency action is required

2005

Energy Policy Act of 2005 amended Subtitle I of the Solid Waste Disposal Act

- Added new leak detection and enforcement provisions to the program

- Required that all regulated USTs be inspected every three years

- Expanded the use of the LUST Trust Fund

- Required EPA to develop grant guidelines regarding operator training, inspections, delivery prohibition, secondary containment, financial responsibility, public record, and state compliance reports on government USTs

- Required EPA to develop a strategy and publish a report regarding USTs in Indian Country

2009

American Recovery And Reinvestment Act of 2009 (Recovery Act)

- Provided a one-time supplemental appropriation of $200 million from the LUST Trust Fund to EPA for cleaning up leaks from federally regulated USTs.

- Majority of funds ($190.7 million) allocated to states/territories in the form of assistance agreements to address shovel ready sites within their jurisdictions.

2015

The 2015 UST regulation changed certain portions of the 1988 underground storage tank technical regulation in 40 CFR part 280. The changes established federal requirements that are similar to key portions of the Energy Policy Act of 2005. In addition, EPA added new operation and maintenance requirements and addressed UST systems deferred in the 1988 UST regulation. The changes:

- Added secondary containment requirements for new and replaced tanks and piping

- Added operator training requirements

- Added periodic operation and maintenance requirements for UST systems

- Added requirements to ensure UST system compatibility before storing certain biofuel blends

- Removed past deferrals for emergency generator tanks, field constructed tanks, and airport hydrant systems

- Updated codes of practice

- Made editorial and technical corrections

A complete version of the law that governs underground storage tanks (USTs) is available in the U.S. Code, Title 42, Chapter 82, Subchapter IX. This law incorporates amendments to Subtitle I of the Solid Waste Disposal Act as well as the UST provisions of the Energy Policy Act of 2005 and gives EPA the authority to regulate USTs.

Use this link for additional information on EPA's laws, regulations, and policies pertaining to USTs.

Because of the large size and diversity of the regulated community, states and territories are the primary implementers of the UST program.

Who can answer questions about UST systems?

The underground storage tank (UST) program is primarily implemented by states and territories. Your first point of contact is the state or territorial regulatory agency that has jurisdiction where the USTs are physically located. A list of state and territorial UST program offices is provided for your convenience.

If you have an UST question that involves USTs in Indian Country, contact your EPA regional office. EPA has responsibility for, and authority over, USTs in Indian Country.

Why are UST systems regulated?

As of September 2024, 577,365 releases were confirmed from UST systems. For state-by-state data (reported semi-annually) such as the number of active and closed tanks, releases reported, cleanups initiated and completed, inspections, and facilities in compliance with UST requirements, go to the UST Performance Measures.

These releases have been caused by leaks, spills, and overfills from UST systems. These releases can threaten human safety and health as well as the environment because UST systems contain hazardous and toxic chemicals. Fumes and vapors can travel beneath the ground and collect in areas such as basements, utility vaults, and parking garages where they can pose a serious threat of explosion, fire, and asphyxiation or other adverse health effects.

Gasoline, leaking from service stations, is one of the most common sources of ground water pollution. Because approximately one-half of the population of the United States relies on ground water as their source of drinking water, ground water pollution is a serious problem. Many municipal and private wells have been shut down as the result of contamination caused by releases from UST systems.

Preventing and cleaning up releases are the two primary goals of the programs that regulate USTs. Cleaning up petroleum releases is difficult and usually expensive; it is easier and less costly to prevent releases before they happen. The old adage of "an ounce of prevention being worth a pound of cure" is particularly relevant to UST systems.

Who regulates UST systems?

In 1984, Congress directed the U.S. EPA to develop regulations for underground storage tank systems. EPA issued federal regulations, effective December 1988, that delegate UST regulatory authority to approved state programs. States are the primary implementers of the UST program and may have requirements more stringent than the federal regulations. As of March 2024, 39 states (plus the District of Columbia and Puerto Rico) have approved UST programs under the 1988 UST regulation. Thirty states have approved programs under the 2015 federal UST regulation.

You should contact your state or local regulatory agency to learn about requirements that apply to your UST system. However, if your tanks are located in Indian country, you should contact your EPA regional UST program office.

What are the responsibilities of an UST owner or operator?

In 2015, EPA revised the underground storage tank regulations. Below are the requirements for owners and operators.

All federally regulated USTs must:

- Be registered with the appropriate regulatory authority

- Meet leak detection requirements

- Meet spill, overfill, and corrosion protection requirements

In addition owners and operators must:

- Meet financial responsibility requirements

- Perform a site check and corrective action in response to leaks, spills and overfills

- Follow regulatory rules during installation of new tanks and closure of existing tanks

- Maintain records as required

- Have periodic checks performed on corrosion protection and leak detection systems

2015 Requirements

Beginning on October 13, 2015 owners and operators must:

- Notify the implementing agency within 30 days of an UST system ownership change

- Notify the implementing agency at least 30 days before switching to a regulated substance containing greater than 10 percent ethanol, greater than 20 percent biodiesel, or any other regulated substance identified by the implementing agency and maintain records demonstrating the UST system meets the compatibility requirements.

- Test or inspect following repairs to spill prevention equipment, overfill devices, and secondary containment areas.

Beginning on April 11, 2016 owners and operators must:

- Use secondarily contained tanks and piping when installing or replacing these components.

- Use under-dispenser containment when installing new dispenser systems.

Beginning on October 13, 2018 owners and operators must:

- Have trained class A, class B, and class C operators.

- Perform periodic testing of spill prevention equipment and containment sumps used for interstitial monitoring of piping.

- Perform periodic testing of release detection equipment.

- Perform periodic inspections of overfill equipment.

- Perform periodic walkthrough inspections at the UST facility.

- Perform release detection for emergency generator tanks.

Owners and operators of field-constructed tanks and airport hydrant systems previously deferred in the UST regulation must begin meeting the requirements in Subpart K.

UST owners and operators need to contact their implementing agency to receive specific information on requirements for their tanks. If the tanks are located in Indian country, then you should contact the EPA regional office.

EPA's regulations concerning USTs are contained in 40 CFR Part 280, 40 CFR Part 281 and 40 CFR Parts 282.50-282.105. The regulations are divided into three sections: technical requirements, financial responsibility requirements, and state program approval objectives.

What are my reporting responsibilities as an owner or operator?

You need to report to your implementing agency on the following occasions:

- When you install an UST, you have to fill out a notification form and submit it to your implementing agency. This form provides information about your UST, including a certification of correct installation. (You should have already used this form to identify your existing USTs. If you haven't done that yet, be sure you do so now.)

- You must report suspected releases to your implementing agency. If a release is confirmed, you must also report follow-up actions you plan or have taken to correct the damage caused by your UST

- You must notify the regulatory authority 30 days before you permanently close your UST

- 2015 Requirement: Beginning on October 13, 2015 when you assume ownership of an UST system, you must fill out a notification of ownership change form and submit it to your implementing agency within 30 days of acquiring the UST system

- 2015 Requirement: Beginning on October 13, 2015 you must notify the implementing agency at least 30 days before you switch to a regulated substance containing greater than 10 percent ethanol, greater than 20 percent biodiesel, or any other regulated substance identified by the implementing agency

- 2015 Requirement: Not later than October 13, 2018 owners of airport hydrant systems and field-constructed tanks must submit a one-time notification of existence for these UST systems using the notification form

You should check with your implementing agency about the particular reporting requirements in your area, including any additional or more stringent requirements than those noted above. A list of state UST contacts is provided for your convenience.

More information about reporting and recordkeeping.

Are heating oil tanks regulated?

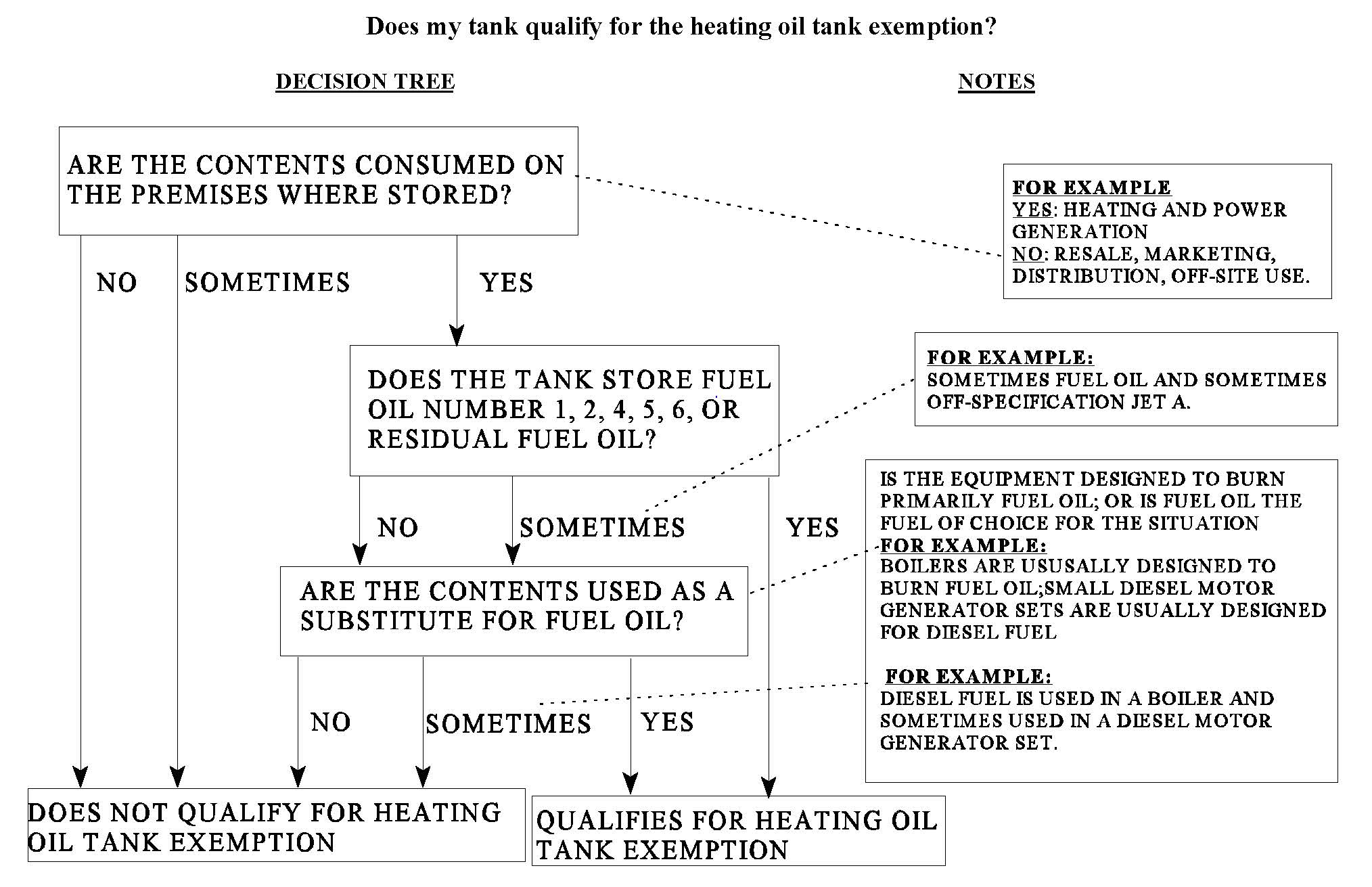

Tanks used for the storage of heating oil for consumptive use on the premises where stored are excluded from federal UST regulations. However, state or local regulatory agencies may regulate these tanks. You should contact your state or local regulatory agency for more information. EPA developed the flow chart below to aid you in determining whether your UST qualifies for the heating oil tank exemption.

Heating oil includes several grades of petroleum fuel oils: No. 1, No. 2, No. 4-light, No. 4-heavy, No. 5-light, No. 5-heavy, No. 6, Navy Special Fuel Oil, and Bunker C. No.2 diesel fuel and kerosene are not defined as heating oil, but are considered a substitute for heating oil when used for heating purposes only.

Consumptive use is not intended to be limited to heating purposes only: the definition extends to any on-site use including heating, generating emergency power, and generating steam, process heat, or electricity. The exclusion does not apply to tanks storing heating oil for resale.

The premises is not limited to the building where the heating oil is stored; it includes anywhere on the same property. Thus, centralized heating units using heating oil that serve more than one building on the same property would qualify for exclusion.

What are the requirements for hazardous substance USTs?

In 2015, EPA revised the underground storage tank (UST) regulations. Below are the requirements for hazardous substance USTs.

UST systems that store substances identified as being hazardous under the Comprehensive Environmental Response, Compensation, and Liability Act (CERCLA) are subject to the same requirements as petroleum UST systems, including secondary containment. Hazardous wastes are already regulated under Subtitle C of the Resource Conservation and Recovery Act (RCRA) and therefore are not covered by the UST regulations.

Currently about 1,200 substances (excluding radionuclides) are identified as hazardous under CERCLA (see 40 CFR 302, section 302.4).

What Is Secondary Containment?

All hazardous substance USTs must have secondary containment. A single-walled tank is the first or primary containment. Using only primary containment, a leak can escape into the environment. But by enclosing an UST within a second wall, leaks can be contained and detected quickly before harming the environment.

There are several ways to construct secondary containment:

- Placing one tank inside another tank or one pipe inside another pipe (making them double-walled systems)

- Lining the excavation zone around the UST system with a liner that cannot be penetrated by the hazardous substance

What About Leak Detection?

The hazardous substance UST must use interstitial monitoring for leak detection. Interstitial monitoring can indicate the presence of a leak in the confined space between the first and the second wall. Several devices are available to monitor this confined interstitial space. The UST regulations describe these various methods and the requirements for their proper use.

If your UST system was installed before October 13, 2015 you can apply for an exception, called a variance, from the requirement for secondary containment and interstitial monitoring. To obtain a variance you must demonstrate to the regulatory authority that your alternative leak detection method will work effectively by providing detailed studies of your site, proposed leak detection method, and available methods for corrective action.

What About Spill, Overfill, and Corrosion Protection?

All UST systems are required to have spill, overfill, and corrosion protection.

What If You Have A Hazardous Substance Release?

Whether you have a confirmed release, or even if you suspect that you might have a release, you must follow the basic actions described below:

- You must take necessary and appropriate steps to stop further release and contain what has been released to ensure that there are no immediate threats to the safety and health of those nearby.

- You must immediately report hazardous substance spills or overfills that meet or exceed their reportable quantities to the National Response Center at 800 424-8802.

- You must also report hazardous substance spills or overfills that meet or exceed their reportable quantities to your implementing agency within 24 hours. However, if these spills or overfills are smaller than their reportable quantities and are immediately contained and cleaned up, they do not need to be reported.

- Based on the information you have provided, the implementing agency will decide if you must take further action at your site.

Are aboveground storage tanks regulated?

Only those tanks that meet the definition of an underground storage tank (UST) system are covered by the UST regulations. Aboveground storage tanks (ASTs) are subject to other federal, state, or local regulations.

Most ASTs need to meet U.S. EPA's Spill, Prevention, Control, and Countermeasure (SPCC) requirements (40 CFR, Part 112).

Some ASTs may need to meet additional state or local regulatory requirements that safeguard human health and the environment from potential threats posed by ASTs. You should check with your state agency in charge of oil pollution control activities for information on state and local requirements.

How many UST systems have leaked? How many have been cleaned up?

States and territories have been submitting information about their UST programs since 1988. As of September 2024:

- 577,365 confirmed releases have been reported.

- 522,031 cleanups have been completed.

For state by state data (reported semi-annually), such as the number of active and closed tanks, releases reported, cleanups initiated and completed, inspections, and facilities in compliance with UST requirements see the UST Performance Measures.

How are UST systems that were deferred in the 1988 UST regulation handled today?

In 2015, EPA revised the underground storage tank (UST) regulations.

In the 2015 UST regulations effective on October 13, 2015, EPA moved some UST system categories from deferred to partially excluded. For other categories, EPA removed the deferral and now regulates those UST systems. The following are partially excluded from the UST regulation.

- Wastewater treatment tank systems that are not already completely excluded from the UST regulation;

- UST systems containing radioactive material regulated under the Atomic Energy Act of 1954; and

- UST systems that are part of an emergency generator system at nuclear power generation facilities licensed by the Nuclear Regulatory Commission (NRC) and subject to NRC requirements regarding design and quality criteria.

These partially excluded UST systems must continue to meet the installation requirements in subpart A and the release response and corrective action requirements in subpart F.

In addition, aboveground storage tanks that are part of an UST system associated with airport hydrant fuel distribution systems and UST systems with field-constructed tanks are partially excluded from the UST regulation. The installation requirements in subpart A and release response and corrective action requirements in subpart F apply to these aboveground components of the UST system.

The following types of UST systems are no longer deferred from the UST regulation:

- UST systems that store fuel solely for use by emergency power generators;

- Airport hydrant fuel distribution systems that meet the UST system definition; and

- UST systems with field-constructed tanks.

Click on each link for more information about how these UST systems are now regulated.

Regulations governing these systems can be found here.

Prevention

What records must I keep?

In 2015, EPA revised the underground storage tank (UST) regulations. Below are the requirements for recordkeeping.

You will have to keep records that can be provided to an inspector that prove your facility meets certain requirements. These records must be kept long enough to show your facility's recent compliance status in the major areas listed below. You should check with your implementing agency about the particular recordkeeping requirements in your area.

- You will have to keep records of leak detection performance and maintenance:

- The last year's monitoring results, and the most recent tightness test

- Copies of performance claims provided by leak detection manufacturers

- Records of recent maintenance, repair, and calibration of on-site leak detection equipment

- You will have to keep records showing the required inspections and tests of your corrosion protection system

- 2015 Requirement: Beginning on October 13, 2015 you must keep records of testing and inspections associated with operation and maintenance once you begin conducting those activities. Operation and maintenance activities include: release detection equipment testing, spill prevention equipment testing, overfill prevention equipment inspections, containment sump testing, and walkthrough inspections

- You must keep records showing that a repaired or upgraded UST system was properly repaired or upgraded

- For at least 3 years after closing an UST, you must keep records of the site assessment results required for permanent closure. (These results show what impact your UST has had on the surrounding area.)

- You must keep records that document your financial responsibility, as explained in EPA's booklet, Dollars And Sense

More information about reporting and recordkeeping.

How can I choose a leak detection method and make sure it works?

In 2015, EPA revised the underground storage tank (UST) regulations.

2015 Requirement: Beginning on April 11, 2016 when owners and operators install or replace tanks and piping, that equipment must be secondarily contained and monitored for releases using interstitial monitoring. Interstitial monitoring will work for secondarily contained tanks and piping because there is a space between the primary and secondary containment areas that can be monitored for leaks. More information about the secondary containment requirements can be found here.

For UST systems installed before April 11, 2016 there is no one leak detection system that is best for all sites, nor is there a particular type of leak detection that is consistently the least expensive. Each leak detection method has unique characteristics. For example, vapor detection devices work rapidly and most effectively in porous soils, while liquid detectors are only appropriate for areas with a high water table.

Identifying the best leak detection choice for your UST depends on a number of factors including cost (both initial installation cost and long-term operation and maintenance cost), facility configuration (such as complexity of piping runs and manifolded tanks), ground water depth, soil type, seasonal rainfall and temperature ranges, availability of experienced installers, and other variables.

You should look around extensively for experienced, professional vendors and installers of leak detection. Ask questions that help you find the most reliable, cost-effective leak detection for your type of facility. Some possible information sources are: references from fellow UST owners, oil marketers, equipment suppliers, trade journals, trade associations, state and local trade associations (especially those for petroleum marketers and UST owners), and state and local regulatory authorities. EPA maintains a list of state and territorial UST programs.

And once you have chosen your leak detection method, you must operate and maintain (O&M) it so that it functions correctly week after week. Good O&M of your UST system and its multiple parts can help you avoid leaks.

Can UST systems be repaired?

In 2015, EPA revised the underground storage tank (UST) regulations. Below are the requirements for tanks and piping, spill, overfill, and containment sumps.

You can repair a leaking tank if the person who does the repair carefully follows industry codes and standards that establish the correct way to conduct repairs.

Tanks and Piping

Within 30 days of the repair, you must prove that the tank repair has worked by doing one of the following:

- Have the tank inspected internally or tightness tested following standard industry codes; or

- Use one of the monthly leak detection monitoring methods; or

- Use other methods approved by the regulatory authority.

Metal pipe sections and fittings that have released product as a result of corrosion or other damage must be replaced. Loose fittings can be tightened, and in some cases that may solve the problem.

Piping made of fiberglass-reinforced plastic can be repaired, but only in accordance with the manufacturer's instructions or national codes of practice. Within 30 days of the repair, piping must be tested in the same ways noted above for testing tank repairs (except for internal inspection).

Within 6 months of repair, USTs with cathodic protection must be tested to show that the cathodic protection is working properly.

2015 Requirement: Beginning on October 13, 2015 if you repair secondary containment areas of tanks and piping used for interstitial monitoring area, you must test the secondary containment area for tightness within 30 days of the repair. The test must be according to manufacturer’s instructions, a code of practice developed by a nationally recognized association or independent testing laboratory, or according to requirements established by the implementing agency.

2015 Requirement for Spill, Overfill, and Containment Sumps (beginning on October 13, 1015)

Within 30 days of repairing any spill or overfill prevention equipment, owners and operators must test or inspect the equipment according to the operation and maintenance requirements, as appropriate, to make sure it is operating properly.

Within 30 days of repairing any containment sumps used for interstitial monitoring of piping, owners and operators must test the containment sump to make sure it is tight. The test must be according to manufacturer’s instructions, a code of practice developed by a nationally recognized association or independent testing laboratory, or according to requirements established by the implementing agency.

Records

You must keep records for each repair until the UST system is permanently closed or undergoes a change-in-service.

Cleanup

How can I tell if a release has occurred?

Various warning signals can indicate that your underground storage tank (UST) may be leaking and creating problems for the environment and your business. You can minimize these problems by paying careful attention to early warning signals and reacting to them quickly before major problems develop.

You should suspect a leak when you discover any of the following warning signals:

- You, your coworkers, or customers smell escaped product or see anything like an oily sheen on water near the facility.

- Your neighbors complain of vapors in their basements or about water that tastes or smells like petroleum.

- Someone reports unusual operating conditions at your facility, such as erratic behavior of the dispensing pump.

- You receive or generate results from leak detection monitoring and testing that indicate a leak.

If you suspect that a release may have occurred, you must immediately notify your state or local implementing agency. If your tank is in Indian Country, then you must contact the EPA regional UST program office. Quick action on your part can minimize the extent of environmental damage and the threat to human health and safety, and it can minimize your share of the high costs that can result from cleaning up extensive releases and responding to third-party liability claims. See the answer to "How Do I Report A Release From An UST System?" for more details on reporting releases.

How do I report a release from an UST system?

If a release from an underground storage tank (UST) system is suspected, the owner or operator must report the release to the state or local implementing agency within 24 hours, or another reasonable time period specified by the implementing agency. If the leak takes place in Indian Country, then the EPA’s regional UST program should be contacted.

Steps should also be taken immediately to stop the release and ensure that there is no threat to the safety of persons in the vicinity of the release.

It is not necessary to notify the implementing agency of aboveground spills or overfills of petroleum of less than 25 gallons (or another reasonable amount specified by the implementing agency) if the release can be contained and cleaned up within 24 hours. It is also not necessary to notify the implementing agency of a spill or overfill of a hazardous substance which results in a release to the environment that is less than its reportable quantity under CERCLA if it can be contained and cleaned up within 24 hours (for more information see 40 CFR 302.5 of CERCLA.)

What do I do about UST releases?

You need to call your implementing agency and report suspected leaks. Then find out quickly if these suspected leaks are actual leaks using the following investigative steps:

- Conduct tightness testing of the entire UST system

- Check the site for additional information on the presence and source of contamination.

You must respond quickly to any evidence of leaked petroleum that appears at or near your site. Your response to confirmed releases comes in two stages: short-term and long-term.

Short-Term Actions

- Take immediate action to stop and contain the release.

- Report the release to the implementing agency within 24 hours. However, petroleum spills and overfills of less than 25 gallons do not have to be reported if you immediately contain and clean up these releases.

- Make sure the release poses no immediate hazard to human health and safety by removing explosive vapors and fire hazards. Your fire department should be able to help or advise you with this task. You must also make sure you handle contaminated soil properly so that it poses no hazard (for example, from vapors or direct contact).

- Remove petroleum from the UST system to prevent further release into the environment.

- Find out how far the petroleum has moved and begin to recover the leaked petroleum (such as product floating on the water table). Report your progress and any information you have collected to your implementing agency no later than 20 days after confirming a release.

- Investigate to determine if the release has damaged or might damage the environment. This investigation must determine the extent of contamination both in soils and ground water. You must report to the regulatory authority what you have learned from an investigation of your site according to the schedule established by the implementing agency. At the same time, you must also submit a report explaining how you plan to clean up the site. Additional site studies may be required.

Long-Term Actions

Based on the information you provided, the implementing agency will decide if you must take further action at your site. You may need to develop and submit a Corrective Action Plan that shows how you will meet requirements established for your site by the implementing agency.

How do you close tanks?

UST systems in use on or after December 22, 1998 must meet the closure requirements at 40 CFR 280.70 when an owner and operator decides to close the UST system. You can close your UST temporarily or permanently. In either case, USTs must be closed properly. For more information on closing tanks, see Meeting UST Requirements.

How much do cleanups cost?

The cost of cleanup depends on a variety of factors, including the extent of contamination and state cleanup standards. The average cleanup is estimated to cost $154,000. If only a small amount of soil needs to be removed or treated, cleanup costs may be as low as $10,000. However, costs to clean more extensive soil contamination may exceed $154,000. Corrective action for leaks that affect ground water typically cost from $100,000 to over $1 million, depending on the extent of contamination.