Pre-Rinse Spray Valves

Pre-rinse spray valves—often used in commercial and institutional kitchens—are designed to remove food waste from dishes prior to dishwashing. By switching to a high-efficiency pre-rinse spray valve, a commercial or institutional kitchen can save more than $110 annually in energy and water costs.

On This Page:

Rinse With Power

After offering a WaterSense label for efficient, high-performing pre-rinse spray valves for several years, WaterSense has successfully transformed the marketplace for commercial kitchen pre-rinse spray valves. The U.S. Department of Energy (DOE) adopted the WaterSense efficiency threshold and performance test for the national energy regulation covering these devices. Therefore, WaterSense sunset its specification for pre-rinse spray valves, effective January 1, 2019. The revised federal regulation requires every pre-rinse spray valve sold in the United States to meet or exceed the efficiency criteria that were established in the previous WaterSense specification. Closing out the specification allows WaterSense to direct its resources to address other products and practices that save water.

EPA first released the WaterSense Specification for Commercial Pre-Rinse Spray Valves in 2013, which allowed products to bear the WaterSense label if they met the WaterSense criteria for water efficiency. EPA’s specification also included spray force criteria and lifecycle testing to ensure performance in commercial kitchens. In 2016, DOE revised the federal energy conservation standards for commercial pre-rinse spray valves, codified in 10 CFR 431 Subpart O. The regulation, effective January 28, 2019, classifies pre-rinse spray valves into three product categories, differentiated by spray force, each with its own maximum allowable flow rate.

| Product Class by Spray Force | Maximum Flow Rate (gpm) |

|---|---|

| Product Class 1 (≤ 5.0 ozf) | 1.00 |

| Product Class 2 (> 5.0 ozf and ≤ 8.0 ozf) | 1.20 |

| Product Class 3 (> 8.0 ozf) | 1.28 |

Source: DOE, 2016

Replacing existing, non-efficient pre-rinse spray valves flowing at 1.6 gallons per minute (gpm) or greater with high efficiency, DOE-compliant models offers a significant opportunity for water and cost savings within commercial kitchens. A total of 30 models of pre-rinse spray valves had earned the WaterSense label by the time EPA sunset the WaterSense Specification for Commercial Pre-Rinse Spray Valves on January 1, 2019. A list of Pre-Rinse Spray Valves Meeting the WaterSense Specification as of January 1, 2019 is available to view (XLSX).

A High-Efficiency Pre-Rinse Spray Valve Factsheet(1 pp, 774 K, About PDF) is also available in PDF.

Water Savings

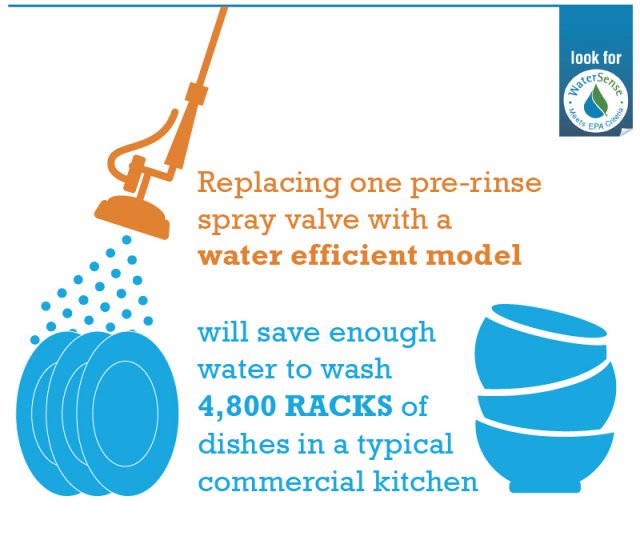

A commercial kitchen that replaces one old, inefficient pre-rinse spray valve with a DOE-compliant model could save as much as $110 to $200 per year, and it could reduce water costs by $65 per year and energy costs by more than $40 per year (natural gas) or more than $130 per year (electricity). The facility could see payback on the investment in as little as five to eight months.

If all commercial food service establishments in the United States installed and used high-efficiency pre-rinse spray valves, we could save more than $215 million in water and energy costs across the country annually.

Performance

When EPA initiated specification development, it identified an existing ASTM test method F2324 that addressed PRSV efficiency and performance. However, stakeholders expressed concern that high-efficiency PRSVs were unsatisfactory and needed to be used longer in the field, negating water savings. EPA initiated a field study to assess water and energy savings, use time, and performance of different models of standard and high-efficiency PRSVs.

EPA found the existing test method did not correlate to user satisfaction and identified that pressure (spray force) played a substantial role in product performance. EPA collaborated with ASTM and other stakeholders through an ASME/CSA Joint Harmonization Task Group to develop a new test method and performance criteria for spray force based on the spray force test developed for showerheads. This test method was ultimately adopted into the existing ASTM F2324 test method for commercial pre-rinse spray valves.

WaterSense labeled PRSVs had to meet performance criteria related to:

- Spray force: Ensures spray force is sufficient to provide user satisfaction (e.g., clean dishes without perceived additional rinsing time).

- Life cycle: Tests whether PRSVs continue to function as intended after their expected use. This criterion was incorporated to address concerns related to leaking and malfunctioning products identified during EPA’s field study.

Soon after the release of the WaterSense specification, the U.S. Department of Energy (DOE) revised the federal energy conservation standards for commercial pre-rinse spray valves. The standard requires the flow rate and spray force to be determined in accordance with the ASTM F2324 standard, which WaterSense, in coordination with its stakeholders, had successfully updated to reflect user satisfaction and performance.

See the Performance Overview for more information on how WaterSense assessed performance when developing the specification.

Specification

As of January 1, 2019, EPA has sunset the WaterSense Specification for Commercial Pre-Rinse Spray Valves; therefore, manufacturers can no longer earn the WaterSense label for these products. WaterSense thanks its program partners and stakeholders for their collaboration in developing and promoting the WaterSense specification.

Implementing rigorous water efficiency and performance criteria across this product category is a major accomplishment for WaterSense, its stakeholders, and water efficiency in commercial and institutional settings. The DOE rule change requiring all pre-rinse spray valves to meet or exceed WaterSense’s previously established criteria reflects the market transformation the program initiated in 2013.

For more information on EPA’s decision to retire the specification, please review EPA’s Notice of Sunset for the WaterSense Specification for Commercial Pre-Rinse Spray Valves, released on October 18, 2018.WaterSense Notice of Sunset of the Specification for Commercial Pre-Rinse Spray Valves (PDF) (8 pp, 407K, About PDF)

WaterSense will maintain the list of WaterSense labeled pre-rinse spray valves in the Product Search Tool until July 2019, after which EPA will retain an archived list for those interested in models that were certified to meet EPA’s efficiency and performance criteria.

To review the original WaterSense Specification for Commercial Pre-Rinse Spray Valves, or for more information about the pre-rinse spray valve specification development process, please visit the Specification for Commercial Pre-Rinse Spray Valves Background Materials page.